Moisture is the enemy of stable slabs. When water infiltrates subgrade soils, it softens support and accelerates settlement. Waterproof Foam addresses the problem at the source by resisting water, filling voids with a closed‑cell structure, and restoring elevation with precision. If you’ve dealt with pooling water, spalling edges, or seasonal heave, pairing a thorough assessment with Concrete Leveling Repair can restore safety and curb appeal without demolition.

What Is Waterproof Foam for Concrete Leveling?

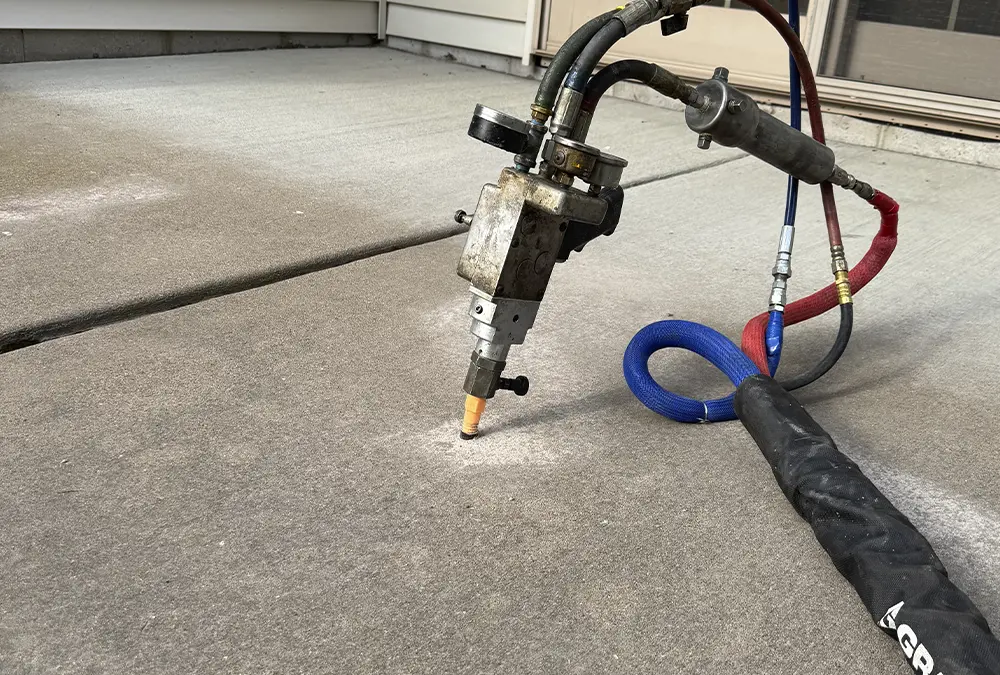

Waterproof Foam is a high‑density, closed‑cell polyurethane engineered to expand beneath a slab, displace water in voids, and stabilize weak soils. Unlike slurry‑based lifts, it doesn’t absorb moisture, it won’t add heavy mass to compromised subgrade, and it cures in minutes, often allowing same‑day return to service. Integrating Concrete Leveling Repair with drainage fixes turns an isolated lift into a long‑term solution.

How It Works vs. Mudjacking

Mudjacking uses a cement‑soil slurry that requires larger ports and adds weight where the soil is already failing. Waterproof Foam expands predictably through small injection ports, seeks voids, and locks the slab in place without water uptake. For homeowners who want a clean worksite and fast access, combining mapping, measured injections, and Concrete Leveling Repair yields stable results with minimal disruption.

Why This Material Wins in the Real World

The right material matters as much as the crew. Waterproof Foam offers:

Precision Lifts

Laser‑guided monitoring and slow‑controlled expansion deliver millimeter‑level accuracy across joints and thresholds. That precision pairs naturally with Concrete Leveling Repair for smooth transitions you can see and feel.

Water Resistance That Protects the Subgrade

Closed‑cell chemistry repels moisture and resists washout. In rainy springs and wet lawns, this resilience keeps voids from re‑forming beneath the slab.

Strength Without Mass

Foam adds negligible weight compared with slurry, reducing the risk of re‑settlement in soft soils. Garage aprons, RV pads, and sidewalks benefit from lift without loading the failure plane.

Speed and Cleanliness

Most drives, patios, and interior slabs reopen the same day. Smaller ports mean minimal patching, and crews can keep landscaping tidy during Concrete Leveling Repair.

Built for Freeze‑Thaw

Closed‑cell structure helps resist water ingress, a critical advantage where seasonal expansion and contraction attack joints and edges.

Ideal Use Cases

Sidewalk lips, settled steps, sloped garage floors, sunken patios, pool decks, and interior slabs with hollow sounds are prime candidates. When seepage, downspout discharge, or poor grading have weakened soils, Waterproof Foam can fill voids and create a water‑resistant base. Tie the lift to Concrete Leveling Repair and a simple drainage tune‑up for durable results.

Best‑Practice Workflow

Step 1. Diagnosis & Moisture Mapping

Trace water paths from rooflines and irrigation, check gutter discharge, note negative grade, and probe for voids. Document elevation variances and define targets for Concrete Leveling Repair.

Step 2. Grid Design & Port Placement

Lay out a mapped grid that respects control joints and load paths. Correct spacing prevents rocking and ensures even lift.

Step 3. Controlled Injection

Inject in pulses, watching laser levels and adjacent thresholds. Waterproof Foam expands predictably; patience avoids overshoot and preserves door clearances.

Step 4. Patch, Seal, and Drainage Fixes

Neatly patch ports, seal control joints, and extend downspouts. Sealing prevents water intrusion that could undermine Concrete Leveling Repair.

Step 5. Walkthrough & Care Plan

Confirm elevations, review photos, and set a maintenance cadence: annual inspections, joint re‑sealing as needed, and seasonal checks after freeze‑thaw.

Cost, Time, and Long‑Term ROI

Replacement demands demolition, forms, new concrete, and days of cure time, not to mention landscape repair. A targeted lift with Waterproof Foam often finishes in a morning and avoids the waste and disruption of full tear‑outs. Upfront pricing can be similar to slurry lifts, but the lifecycle value is higher thanks to moisture resistance and fewer callbacks. Pairing the lift with Concrete Leveling Repair maximizes return on every dollar.

Built for Minnesota’s Climate

Soils around Eagan endure freeze‑thaw cycles that pump fines and open voids beneath slabs. Waterproof Foam helps break the cycle by resisting water ingress while restoring bearing. Combine it with strategic joint sealing and Concrete Leveling Repair to minimize seasonal movement.

For general engineering context on modern concrete maintenance and durability, see the Federal Highway Administration resources.

Mistakes That Undermine Good Work (Avoid These)

Skipping Root‑Cause Fixes

Lifting a slab without addressing downspouts, grading, or irrigation guarantees a return visit. Always fix the water first, then lift.

Random Port Patterns

Even a great material fails with sloppy layouts. Respect the grid, inject evenly, and monitor live. Tie your plan to the scope of Concrete Leveling Repair.

No Joint Sealing After the Lift

Unsealed joints invite water and problems. Seal the same day to protect your investment.

Rushing the Sequence

Let each shot react before the next. Waterproof Foam thrives on patience and measurement.

Maintenance That Keeps Results Locked In

A lift is step one. Keep it performing with simple habits:

- Extend downspouts 6–10 feet from the slab edge.

- Re‑seal joints every 2–3 years or after severe winters.

- Avoid concentrating heavy loads in one spot.

- Schedule a spring check after snowmelt and a fall check before freeze.

A small maintenance plan preserves Concrete Leveling Repair and keeps surfaces smooth.

When a Lift Isn’t the Right Answer

Heaving clays, active utility leaks, or full‑depth fractured slabs may call for soil remediation or selective replacement. A reputable team will recommend the right path, even if that means pausing Waterproof Foam and rebuilding subgrade first.

Why Local Expertise Matters

Crews who understand Minnesota soils, surface drainage, and seasonal timing deliver better outcomes. From the first inspection to the last sealant bead, integrating Concrete Leveling Repair with water management is what turns a quick lift into a long‑term fix. If you want a clean site, fast turnaround, and durable performance, Waterproof Foam is the material to request by name.

Lift Right, Once

Settled slabs don’t need a sledgehammer, they need a smarter approach. Specify Waterproof Foam, insist on a mapped injection plan, and include drainage and joint sealing in the scope of Concrete Leveling Repair. The result is a cleaner project, a faster return to service, and stability that stands up to Minnesota weather.

Ready to restore a safe, even surface? Contact Us Today for a fast assessment.