Mudjacking is an older method for lifting sunken concrete by pumping a thick slurry under the slab to push it back to grade. The material is usually a mix of soil sand and cement blended with water. Crews drill large ports through the slab pump in the slurry and build pressure until the panel rises. The idea is simple use added mass and hydraulic pressure to fill voids and restore elevation. For decades this was the go to approach for uneven sidewalks driveways patios and garage aprons.

How Mudjacking Works from Start to Finish

Site review and setup

The team identifies low areas notes trip edges and marks port locations. Equipment arrives with hoses and a mixer for the slurry. The work area is taped off and the slab surface is cleaned so dust does not interfere with patching later.

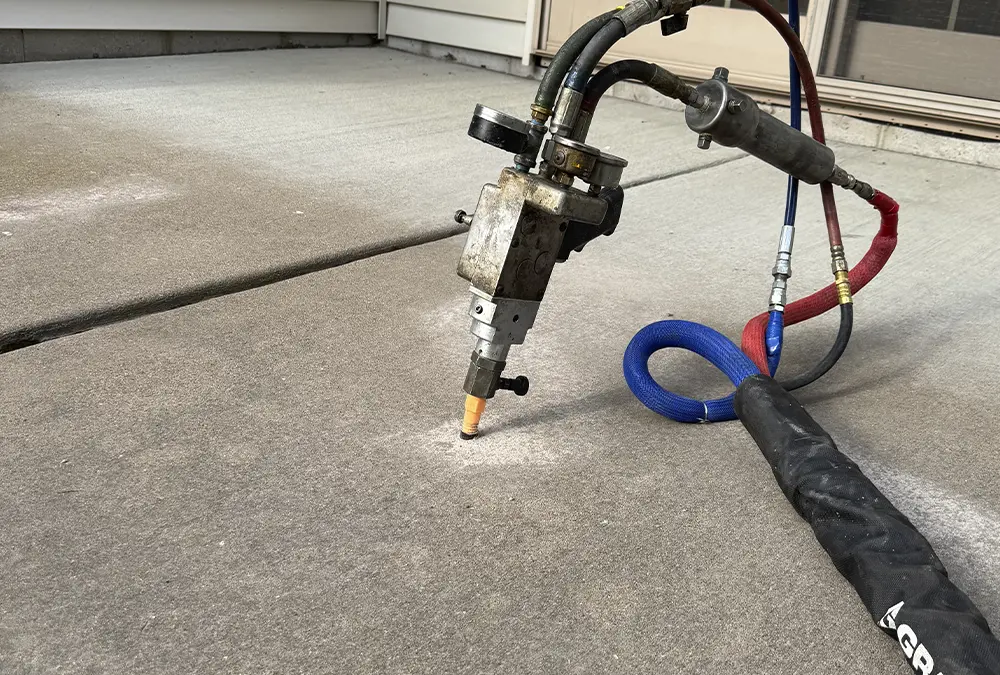

Drilling and pumping

Holes about one and a half to two inches wide are drilled through the slab at the marked points. The slurry is pumped under pressure into the voids. As material spreads it lifts the panel. Workers watch elevations and stop pumps in short pulses so the slab does not overshoot the target level.

Patching and clean up

Ports are filled with concrete plugs and surface patches. The crew washes down the site and the slab is set aside to stiffen before use. Because the slurry holds a lot of water it can take a day or longer before full use is recommended especially for vehicle traffic.

Where Mudjacking Helps and Where It Struggles

Mudjacking can be effective for large voids that need volume under a slab. If the soil is generally stable and the issue is a single hollow zone the slurry fills space and supports the concrete again. That said the method has limits that matter in everyday residential work.

Larger ports and a more visible patch

The ports required for slurry are wide which means larger surface plugs that can be noticeable across a driveway or patio. On decorative concrete this difference is easy to spot.

Added weight on already weak soils

A slab settled because the base soils lost strength or eroded. Adding hundreds of pounds of slurry can stress those same soils and may lead to renewed settling in the future. In wet seasons the heavy fill is vulnerable to washout.

Slower return to service

Because the mixture contains water it needs time to set and drain. That delay can be a problem for busy driveways garage bays and commercial entries that need same day access.

Moisture sensitivity

In areas with freeze thaw cycles water inside a slurry fill can move or expand and reopen voids under the slab.

A Modern Alternative Polyjacking Explained Fairly

Polyjacking uses closed cell polyurethane foam to lift a slab. The foam is injected through small ports and expands in a controlled way. As it expands it seeks voids displaces trapped water and rebuilds support without adding heavy mass. The material cures quickly and is water resistant once set. That is why many homeowners now choose polyjacking services when they compare options.

What you notice on day one

The ports are small which means tiny patches that blend more easily with surrounding concrete. Work areas stay clean because there is no wet slurry splatter. Most residential lifts return to service the same day which is ideal for driveways and garage aprons.

What matters over time

Because the foam is light the base soils are not overloaded. Because it resists water the fill does not wash out during wet seasons. When joint sealing and drainage fixes are included the elevation holds through cycles of weather.

Honest Comparison Mudjacking versus Polyjacking

Precision

Both methods can raise a slab. Foam expansion and small pulse injections make fine adjustments easier at thresholds and steps. This is useful where a door rubs or a lip at a sidewalk needs millimeter level control.

Appearance

Small ports leave smaller patches. On colored or stamped surfaces this is a visible difference that many owners prefer.

Speed

Foam lifts are ready fast. That means parking and walking can resume sooner which saves time and inconvenience.

Long term stability

Added weight from slurry can lead to renewed settlement in soft soils. Lightweight water resistant foam paired with sealing and drainage improvements tends to stay put.

Safety Drainage and the Real Cause of Settlement

No method lasts if water continues to reach the base. Settlement begins when fines move out of the support zone and voids open beneath a panel. Redirect downspouts extend splash lines shape soil to slope away from the house and seal joints the same day as the lift. These steps matter as much as the lift itself whether you choose mudjacking or foam based work.

When Mudjacking Is Not the Right Fit

If soils are soft and wet the added weight of slurry is a concern. If decorative finishes make large plugs undesirable appearance is a concern. If you need to drive on the slab soon after the repair timing is a concern. In each of these cases polyjacking services provide a cleaner faster and often more durable path.

Minnesota Climate Considerations

Freeze thaw cycles push and pull on slabs and on whatever fills the voids beneath them. A closed cell foam that resists water uptake helps avoid pumping and washout during spring thaws and summer storms. That is one reason foam lifts have become the preferred option for many local homeowners.

The Process You Should Expect From a Professional Crew

Assessment and mapping come first with measurements at joints and thresholds and a simple diagram of water paths. Small ports are drilled in planned locations. Injections are made in short pulses while a laser monitors elevation. Ports are patched neatly. Control joints and cracks are sealed and downspouts are extended so water does not return to the support zone. A quick walkthrough confirms slope away from structures and the surface returns to use right away.

Choosing a Partner Who Focuses on Foam Lifts

If you want a tidy site fast return to service and long term stability ask about foam density cure times joint sealing and drainage adjustments. A crew that leads with these details is set up to deliver predictable outcomes. For a clear scope and a modern approach start here polyjacking services and see how a mapped lift can restore safety and curb appeal without demolition.

If you want to start a conversation now use this link Contact us and share a photo and a brief note about your slab. You will receive guidance and a next step that fits your schedule.