Polyjacking brings precision, speed, and cleanliness to walkway restoration across Minneapolis Saint Paul and nearby suburbs. Sidewalks endure freeze thaw cycles, drainage issues, and tree root pressure that slowly loosen the subbase and create uneven joints. When panels tilt or settle, small lips turn into trip points that affect safety, appearance, and accessibility. Instead of tearing out large sections and waiting days for cure time, Polyjacking re establishes uniform support from below and returns paths to use quickly, often the same day. With careful mapping and measured lifts, sidewalks regain smooth transitions that feel natural underfoot and look seamless along curbs, entries, and driveways.

Why sidewalks settle and how Polyjacking fixes the cause

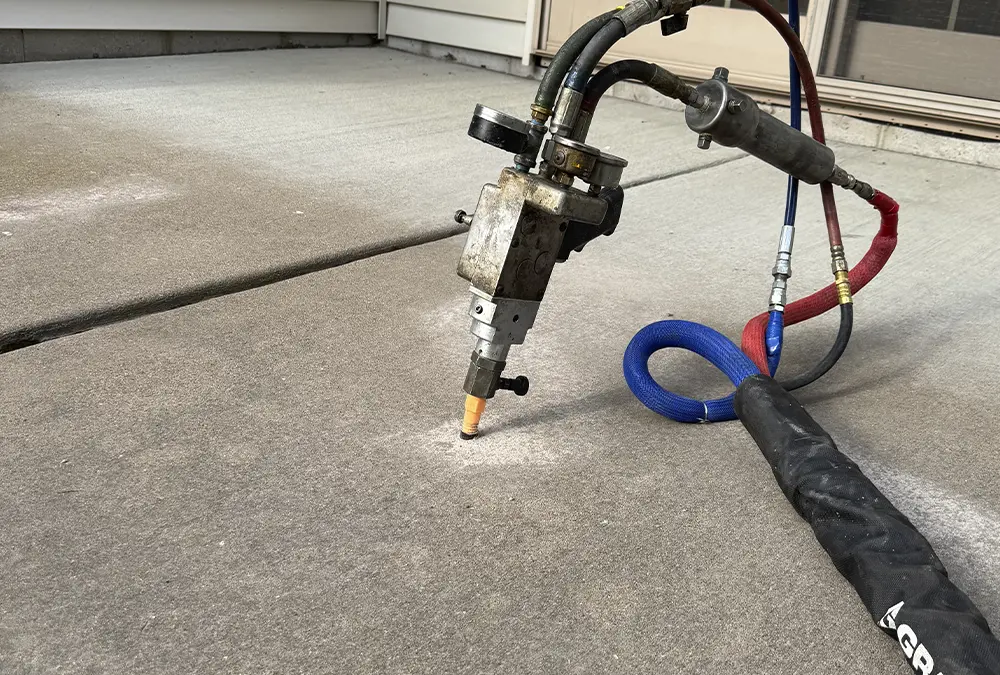

Sidewalk slabs sit on compacted soils that can shift with moisture and seasonal change. Over years, meltwater, irrigation, and gutter discharge migrate fines away from the base and leave voids under panels. Tires at driveway crossings and repeated foot traffic pump those panels, magnifying gaps until edges rock and joints open. Polyjacking addresses the cause by flowing as a liquid to find cavities and expanding into a closed cell, rigid support. Small injection ports minimize visual impact, patching blends neatly, and the structural correction halts the cycle that creates trip hazards in the first place.

Moisture movement erosion and panel separation

This overview explains how water creates hidden voids and why the first signs of trouble can be subtle in neighborhood walks. In spring and after storms, runoff concentrates at low edges and along shaded stretches where evaporation is slow. Water seeps through hairline cracks and joints, carries away fine material, and leaves tiny pockets that the eye cannot see. Each footstep flexes the slab and pumps more material from those pockets until the panel loses contact with its base and begins to rock at the corners.

With contact reduced, movement multiplies. The joint sealant breaks, edges chip, and small lips begin to catch toes and stroller wheels. That is the ideal moment for Polyjacking, which restores a continuous base before damage spreads across adjoining panels. By filling voids and locking the slab back onto a firm foundation, the repair eliminates the pumping action and keeps water from re entering the same pathways. The sidewalk looks unchanged on top yet feels solid everywhere.

As the base stabilizes, follow up sealing becomes effective again. Joints accept sealants that stay intact because panels no longer work against one another. Runoff follows the intended slope to the gutter rather than sinking into openings. With structure corrected, routine care like sweeping and cleaning delivers more value and keeps the surface comfortable and safe.

Freeze thaw cycles tree roots and curb transitions

This overview introduces how seasonal swings and roots combine to amplify misalignment. In northern climates, temperatures cross the freezing point often, expanding water in pores and joints. Those cycles push at slab edges and amplify any loss of support beneath. Tree roots searching for moisture can lift one side while washout drops another, creating opposing forces that widen gaps. At drive aprons and curbs, traffic loads highlight those weaknesses and quickly produce trip points that draw complaints.

Polyjacking neutralizes those forces by re establishing uniform bearing across the panel. With the slab supported everywhere, expansion and contraction are more even and less likely to pry joints apart. The targeted nature of the work respects roots and landscaping while correcting the plane of the walk. Corners settle into solid footing, lips close, and transitions align smoothly with curbs and entries so wheels glide and feet land flat.

When panels carry utilities or lighting conduits nearby, the small diameter injection ports avoid conflicts and keep the site neat. Crews adjust lift in fractions of an inch to meet surrounding elevations without bending the slab. The result is a restoration that looks quiet and simple on the surface because the real change happens out of sight where support matters most.

Benefits of Polyjacking for neighborhood sidewalks and campus walks

Choosing a repair method is about safety, uptime, and long term performance. Polyjacking excels because it is quick to set up, fast to cure, and hydrophobic, so support remains strong even when soils are wet. For homeowners, managers, and public works teams, that means shorter closures and fewer return visits. Smooth joints reduce liability exposure and keep routes accessible for all ages and abilities.

Clean workflow fast return to service and minimal disruption

This overview covers how Polyjacking delivers practical benefits on busy routes where people need to keep moving. Equipment is compact and tidy, and injection ports are small and strategically placed. Technicians lift in small increments and confirm alignment with levels, so transitions meet cleanly at entries, steps, and crosswalks. Because the foam cures rapidly, most paths reopen quickly, which matters near schools, parks, and storefronts where pedestrian traffic is constant.

The clean process also protects landscapes. Lawns, beds, and edging remain intact, and there is no slurry or heavy demolition to haul away. Neighbors appreciate the quiet, and the finished look blends with existing textures. That combination of speed, cleanliness, and precision defines the homeowner friendly character of Polyjacking and makes it ideal for HOA and municipal work where appearance and uptime are priorities.

With closures minimized, safety improves immediately. Trip points that once caught toes disappear, stroller wheels roll smoothly, and carts glide without wobble. Those everyday comforts are the most noticeable outcome and the reason many communities standardize on Polyjacking for recurring settlement zones. The fix addresses cause and effect rather than covering symptoms.

Hydrophobic support durability and seasonal resilience

This overview explains why closed cell foam performs in wet and cold conditions. The material used in Polyjacking rejects liquid water and resists washout, so the lift you see on day one stays through storms and thaw cycles. By stopping the pumping action under traffic, the foam prevents new voids from forming along the same paths. The stabilized base spreads loads evenly, reducing edge chipping and protecting joint sealants from shear.

Seasonal swings still occur, but with uniform support, panels move together instead of prying apart. That means fewer cracks, fewer puddles, and longer intervals between maintenance. The practical outcome is a sidewalk that feels solid every day and keeps its clean lines from spring through winter. For property managers, that reliability simplifies planning and reduces emergency calls after big weather events.

Durability is reinforced by the precise way lifts are performed. Incremental adjustments allow control within fractions of an inch, and patching blends with surrounding textures. The result is a restoration that looks natural because it respects how the original walk was set while correcting what time and water changed underneath.

Local use cases and planning across the Twin Cities

Neighborhoods in Eagan, Apple Valley, Burnsville, and throughout Minneapolis Saint Paul share similar patterns. Low spots near downspouts, shade lines beside fences, and edges at driveway crossings show settlement first. Polyjacking fits these conditions well because access is tight and residents value quick, tidy results. Coordinating with seasonal maintenance—joint sealing, gutter cleaning, and grading touch ups—multiplies the benefit and keeps routes reliable year round.

Residential blocks townhome paths and park trails

This overview highlights common settings where smooth access matters daily. In residential areas, mail routes and school walkways must remain safe for all users. Townhome communities see concentrated traffic on shared paths, and parks receive heavy weekend use. Each location benefits from targeted lifts that eliminate trip points without tearing out large sections or disrupting plantings. Crews can move panel by panel and reopen segments progressively as work advances.

Once voids are filled and panels set, drainage follows the intended slope rather than collecting at lip edges. Strollers, scooters, and walkers experience steadier footing, and winter plowing goes more smoothly because edges align. Routine tasks like sweeping sand after thaw or rinsing spring pollen become easier on flat surfaces. Residents notice the difference immediately and often request the same approach on other blocks when they see the clean result.

Public spaces benefit from documentation that accompanies precise lifts. Level readings and photos show how grades changed and support planning for future touch ups. Those records help boards and parks departments prioritize work efficiently and communicate clearly with residents about progress and safety.

Business districts campus loops and facility perimeters

This overview explains how Polyjacking supports accessibility and appearance where customers, students, and staff move every day. Storefronts depend on smooth entries for carts and wheelchairs, and campus loops must meet expectations for comfort and code. Facility perimeters carry maintenance traffic that can stress weak panels. With Polyjacking, teams correct trouble spots quickly, keep aesthetics high, and avoid blocking doors for long periods.

Because the method is tidy and fast, scheduling can align with off hours to reduce impact. Incremental lift maintains door clearances and keeps mats and thresholds in place. Edges near curbs realign to guide water to drains rather than along the building line. The finished result supports both brand impression and day to day convenience.

For managers, the low disturbance footprint reduces risk to landscaping, signage, and utilities. The repaired areas blend with the original look so the improvement reads as a quality standard rather than a patch. That quiet professionalism is part of why Polyjacking has become a go to solution for sidewalks in high visibility areas.

Process best practices that produce even, lasting walks

Good outcomes follow a disciplined workflow that diagnoses, corrects, and protects. Polyjacking is most effective when paired with simple water management and seasonal maintenance. The aim is to remove the mechanism that created the hazard and keep it from returning.

Assessment mapping and step by step lift sequence

This overview introduces the inspection and planning steps. Technicians listen for hollow sounds, map rocking edges, and mark low panels. Reference elevations at doors, curbs, and adjacent slabs guide target heights. Injection ports are placed on a grid that follows the void map and avoids utilities. Work proceeds from the lowest edges inward to prevent stress concentrations.

Foam is introduced in measured quantities so rise can be observed and confirmed with levels. Lifts occur in small increments, often a quarter inch at a time, to protect the slab and align joints precisely. As continuous support is restored, rocking stops, lips close, and the panel sits firmly on its base. Ports are patched and textures blended for a discrete finish that preserves curb appeal.

A final pass checks slope toward drainage paths and identifies joints that would benefit from sealant. The team notes simple grading or downspout adjustments that keep water moving. With structure restored and water managed, the sidewalk performs reliably across seasons.

Joint sealing drainage tuning and seasonal care

This overview covers post lift steps that lock in gains. Joint sealants prevent water from re entering at vulnerable lines, and penetrating sealers reduce surface absorption. Extending downspouts, adjusting splash blocks, and confirming positive grade away from edges keep meltwater and rain from loading the subbase. Where snow removal occurs, markers help operators avoid blade strikes at joints.

Seasonal checkups focus on quick wins. Resealing at recommended intervals keeps absorption low and joints flexible. Sweeping grit and deicing residue reduces abrasion that can open small chips. A few minutes of routine care stretch the time between structural interventions and keep the walk looking fresh.

Neighbors benefit when connected panels are addressed together. Correcting one low slab in isolation can shift water toward the next. Coordinated improvements maintain uniform grades and keep the entire route comfortable. Consistency is the quiet secret behind sidewalks that feel good year after year.

Costs timelines and value for property owners and managers

Budgets weigh direct costs, downtime, and site impact. Replacement means demolition, forms, new placement, and curing days, along with risks to landscaping and utilities. Polyjacking avoids most of that disruption and typically returns sidewalks to service quickly. While every site is unique, the combination of speed, cleanliness, and durable support makes the method compelling across neighborhoods and campuses alike.

What shapes price scope site conditions and access

This overview sets expectations for estimates and scheduling. Total area, number of panels, depth and spread of voids, and accessibility drive planning. Heavily washed zones can require more material and time. Including joint sealing and small drainage adjustments in the scope protects the new base and extends the life of the lift, often at modest additional cost.

Prioritizing the worst trip points first reduces risk immediately, then adjacent panels can be aligned for a continuous feel. Many jobs fit comfortably into a single day with progressive reopenings as sections are completed. That agility suits busy neighborhoods and facilities that cannot afford long closures.

The low disturbance footprint preserves landscaping, signage, and edging. Because the finished look blends with existing textures, the result reads as a maintenance standard rather than a patch. The property gains safety and polish without the mess or delay of tear out.

Simple maintenance habits big returns over time

This overview explains how small routines keep sidewalks even. Sweeping grit away from joints, keeping gutters clear, and maintaining sealants block the moisture that undermines bases. Monitoring for early signs like rocking corners or hollow sounds allows quick intervention before gaps widen. These habits magnify the value of the structural fix and keep routes dependable.

Because the foam foundation in Polyjacking is hydrophobic, support holds even during wet seasons. Panels stay aligned, edges resist chipping, and pedestrians enjoy smooth, predictable footing. Those practical comforts are what residents and visitors notice every day, and they are the reason many owners choose this approach after the first successful project.

With structure secure, improvements become about aesthetics and access enhancements. Wayfinding, lighting, and landscaping upgrades shine brighter when the walk beneath is even and well supported. Strong fundamentals make everything else easier.

Walk with confidence

A level sidewalk invites movement and sets a welcoming tone for homes, schools, and businesses. If joints have lifted or dropped, measured lifts restore comfort and accessibility quickly and cleanly. Polyjacking corrects the base cause of trip hazards, keeps surfaces aligned through seasons, and pairs with simple care that anyone can manage. Bring your block back to smooth, safe passage and enjoy routes that feel right under every step.

Leveling keeps routes safe tidy and comfortable for all ages. When it is time to schedule, please contact our team.