Polyjacking has become the quiet advantage inside busy warehouses where every second of uptime matters. Pallet jacks and forklifts amplify tiny slab movements into real delays—wobbly loads, rattling transitions, and safety slowdowns at dock doors. Instead of ripping out concrete and waiting days for cure, Polyjacking restores support from below with hydrophobic foam that lifts precisely, stabilizes voids, and brings joints back into alignment. The result is smoother traffic, less equipment wear, and cleaner workflows that keep teams moving at full speed. These improvements align with adjacent Leveling and Lifting needs across connected bays.

Why warehouse slabs settle and what it means for daily operations

Expansive soils, repeated point loads, and drainage paths that run along walls gradually pull fines from the subbase and leave hidden voids. Forklifts pump panels as they bounce over lips, and every pass grows the gap a little more. Over time, the floor goes from almost flat to visibly uneven at aisles and thresholds. By re establishing continuous bearing beneath the slab, Polyjacking eliminates the pumping mechanism, closes gaps at joints, and brings the surface back to the plane your racking and automation expect.

Load cycles moisture migration and edge degradation

This overview introduces how routine forces create settlement patterns inside distribution spaces. Aisles with tight turning radii see concentrated tire paths that stress the same spots repeatedly. Moisture from cleaning, snow tracked in at docks, or small roof leaks migrates to low edges and fine cracks. As water moves, it carries fines from the base, creating small cavities that the eye cannot see but wheels can definitely feel.

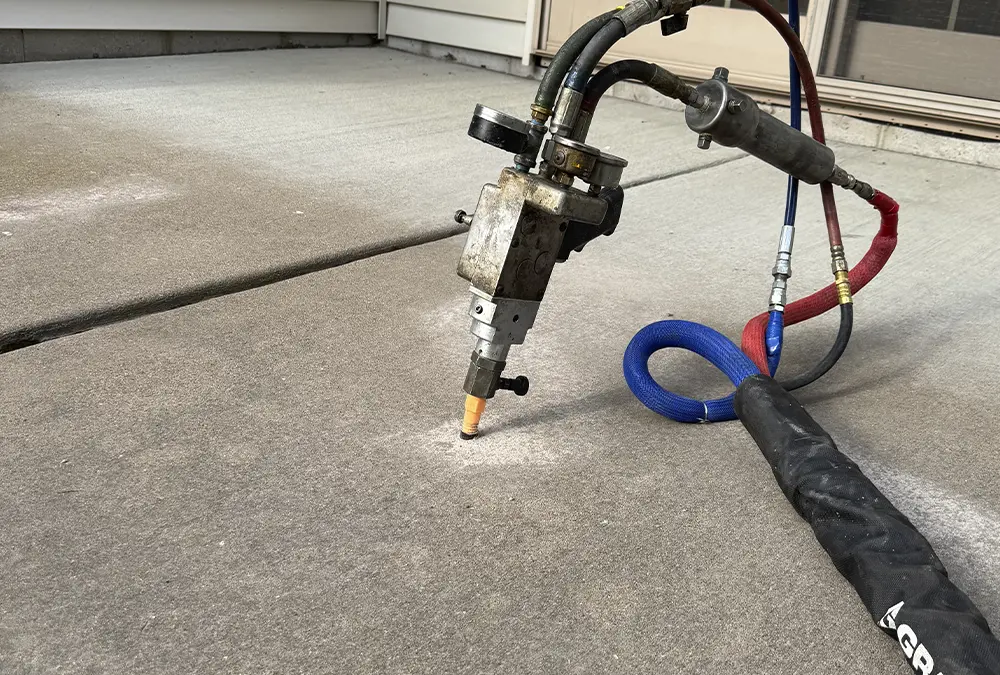

Forklifts hit those zones at speed, flexing the slab and pushing air and fines back and forth until contact with the base is lost. The joint sealant breaks, small chips appear, and lips start catching wheel forks or pallet corners. Polyjacking addresses the cause, not just the symptom, by filling voids in liquid form and expanding into a rigid, closed cell support that resists water and traffic. With bearing restored, joints stay tight longer and wheels stop chattering.

As the base unifies, the entire traffic rhythm improves. Operators feel fewer jolts, scanners stay readable on the move, and stacked loads ride with less sway. Those tiny improvements compound across thousands of trips and turn into fewer slowdowns, fewer damaged cartons, and less fatigue over a shift.

Drainage lines dock influence and temperature swings

This overview shows how building features shape settlement you can predict and prevent. Floor drains, dock levelers, and exterior aprons act as moisture magnets. Meltwater from trailers and winter pushbacks concentrates along door lines, where heat loss also makes temperature swings sharper. These conditions loosen support at the exact points where traffic is heaviest.

By planning Polyjacking around these microclimates, crews can lift from the best angles, protecting door thresholds and keeping slopes toward drains intact. Small, incremental lifts keep tension off embedded anchors and dock hardware. The precision of the method restores a clean roll path so operators can maintain speed entering and exiting trailers.

With voids closed and support uniform again, sealants and coatings last longer. Maintenance teams spend less time grinding lips or chasing recurring cracks and more time on proactive care that keeps the floor looking and performing like the backbone of your operation. When future scope includes equipment pads or racking changes, coordinated Installation and selective Replacement become simpler on a stable substrate.

The operational advantages of Polyjacking for warehouse floors

Choosing Polyjacking is about uptime, predictability, and safety. Closed cell foam cures quickly, so aisles reopen in sequence without long shutdowns. Small injection ports patch cleanly, and equipment footprint stays tight—even in narrow rack canyons. The system fits modern, lean operations where every hour has a job.

Faster return to service precise lifts and tidy sites

This overview explains how production keeps moving while floors are corrected. Work zones can be phased one or two bays at a time, with cones and simple signage guiding traffic around the active area. Incremental injections bring panels up by fractions of an inch, verified with levels and string lines so joints meet cleanly without creating new stress elsewhere.

Because the foam used in Polyjacking is hydrophobic, the lift you see on day one holds even when cleaning water or melt reaches the edge. Ports are compact and patch flush, so housekeeping resumes without catching mops or scrubbers. The entire workflow reads as maintenance rather than construction, which makes scheduling easy for operations, and it dovetails with planned Installation windows without slowing shifts.

Precision shows up in the way equipment feels. Trucks that once rattled glide across joints. Battery packs last longer when wheels roll freely, and operators report less vibration over a shift. That comfort is not cosmetic—it protects inventory, scanners, and the people who make the place run.

Lower equipment wear fewer product touches and safer aisles

This overview connects smoother slabs to costs you can measure. Every hard impact steals life from casters, tires, and mast components. When Polyjacking removes lips and stabilizes panels, wheels stop slamming and bearings stop taking shock loads. Inventory rides steadier, so fewer pallets need rewraps or inspection touches after a rough crossing.

Safety improves with stability. Smooth transitions reduce tip risk at corners and protect pedestrians who share space with machines. Because work zones are small and quick to reopen, there is less temptation to cut through closures. The result is cleaner, quieter movement and fewer incident reports competing with production goals.

Savings compound. Fewer repairs, fewer reworks, and fewer minutes lost to detours show up directly in throughput numbers. Floors that feel good to drive on make everything else easier.

Local planning across the Twin Cities and seasonal considerations

Minnesota facilities fight freeze thaw outside and tracked moisture inside from November through April. Planning Polyjacking with seasons in mind keeps schedules realistic and outcomes durable. Windows between cold snaps still allow reliable lifts that carry you into spring.

Winter windows docks and melt management

This overview outlines how to time work near dock doors and cool corners. Choose stretches with a two to three day forecast of stable highs and manageable winds. Crews stage heated water and insulated hoses to keep mixes cooperative, and curing blankets protect patches near exterior doors overnight.

During those windows, Polyjacking focuses on door lines first, where the benefit per hour is highest. As lips close and planes align, meltwater drains instead of pooling, and scrubbers stop catching edges. The first shift sees the difference immediately, and momentum for the next zones builds naturally.

Spring follow ups reseal joints and confirm slopes. With voids closed, new sealant lasts longer and keeps water out next winter. A seasonal cadence turns one project into a long term upgrade.

Summer heat cleaning water and expansion behavior

This overview explains warm weather realities. Cleaning cycles increase, and slabs see stronger expansion during hot afternoons. With uniform bearing restored by Polyjacking, panels move together instead of prying apart. Joints follow designed gaps, coatings stay intact longer, and operators enjoy consistent feel across the day.

Housekeeping teams notice the benefit, too. Pads and brushes last longer when the floor is even, and water recedes along intended paths. Visual standards are easier to maintain when the surface works with you instead of against you.

Predictable floors support predictable output—exactly what peak season demands.

Process best practices to keep production on track

A reliable result is the sum of smart diagnosis, disciplined lift, and small water management tweaks. Polyjacking shines when it is part of a simple, well communicated plan that fits your flow.

Mapping voids sequencing bays and protecting thresholds

This overview details a playbook that respects both structure and operations. Crews start by listening for hollow zones, chalking joints with lift, and setting target elevations at bay entries and crossings. Work proceeds in short segments to maintain egress and keep critical aisles open. Thresholds at offices, coolers, and dock doors get special attention so doors keep sealing and carts roll smoothly.

Injection follows a low to high sequence that avoids bending panels across isolated cracks. Polyjacking expands into cavities and re establishes bearing before the next increment of lift. Levels confirm alignment and photos document progress for your records. With evidence in hand, teams can prioritize which runs to address next.

Patching and cleanup happen in line with production breaks. Ports blend flush, sweepers roll immediately, and signage comes down as soon as hardness checks pass. The floor returns to the rhythm your people expect.

Managing water routes joints and coatings for durability

This overview shows how small maintenance choices extend the value of structural fixes. Joint sealing keeps water out of the subbase where it could restart pumping. Redirecting downspouts, repairing small leaks, and adjusting scrubber settings so water is not dumped at the same edge each day all protect the lift.

Where coatings are planned, Polyjacking should come first so the substrate is stable. Even bearing prevents telegraphed cracks and premature wear patterns. With the foundation right, coatings deliver the cleanable, high visibility surface that safety teams love.

A short checklist—seal joints, verify slopes, confirm no recurring moisture at walls—keeps everything on track long after the crew leaves.

Technical notes that matter to facilities and EHS teams

Facilities, maintenance, and safety leaders ask good questions about materials, loads, and indoor work. Clear answers build confidence and speed approvals without surprises.

Load capacity foam behavior and embedded items

This overview addresses what sits under the wheels. The closed cell foam used in Polyjacking develops high compressive strength and spreads loads broadly rather than point loading the slab. That distribution protects edges and reduces the chance of rocking under mast impacts.

Embedded anchors, conduits, or dowels are considered when placing ports. Lift is incremental, and measurements guard against prying at connections. The aim is a quietly stronger floor that simply feels right to drive on.

Where racking bases overhang a low joint, targeted lifts re establish contact beneath before shims are adjusted. That pairing stabilizes posts and keeps plumb checks consistent.

Indoor air housekeeping and communication

This overview covers how the work coexists with people. Mixing stations sit near exterior access with mats and trays beneath, and HEPA vacuums capture drilling dust at source. Communication boards outline the day’s sequence and when each bay reopens. Housekeeping receives a heads up so sweepers can trail the crew and return shine fast.

Because work zones are compact, emergency egress remains clear. Cones and simple detours keep pedestrians safe without complex reroutes. The experience reads as routine maintenance, not disruption.

A smoother path to throughput

Warehouses run on rhythm. When floors are even, Polyjacking keeps forklifts gliding, operators comfortable, and schedules intact. Small, precise lifts unlock big gains in safety and speed without tearing out slabs or closing aisles for days. If your traffic is telling you the floor is tired, a measured, well documented plan can bring it back in stride and keep peak season humming.

For tailored guidance or to schedule a visit, please contact our team.