Ask any seasoned finisher and they’ll say the same thing: the real boss on placement day is the weather. Temperature, humidity, wind, and precipitation can speed up, slow down, or completely derail your Concrete Installation. Understanding how each element affects hydration and evaporation lets you plan smarter, pour cleaner, and cure stronger, especially in climates like Minnesota where seasonal swings are dramatic.

The Science Behind Weather and Concrete

Fresh concrete is a living system in the first hours after placement. Cement hydration, the chemical reaction between cement and water, creates heat, gains strength, and locks aggregates into a solid matrix. Too much water loss too soon (evaporation) leads to plastic shrinkage cracking; too little evaporation in cold, damp conditions delays the set and can damage the surface if it freezes. That’s why weather‑smart Concrete Installation isn’t optional; it’s foundational.

Heat Fast Sets, Higher Risk of Cracking

What Heat Does

High ambient temps and sun exposure accelerate hydration. The mix gets sticky, finishing windows shrink, and surface moisture flashes off. If you’re not ready with water management and curing controls, you’ll invite plastic shrinkage cracks.

Pro Tactics for Hot‑Weather Concrete Installation

- Cool the mix: Use chilled water or ice in the batch; request morning deliveries.

- Shade and windbreaks: Erect shade cloths; break gusts that drive evaporation.

- Set‑retarding admixtures: Extend workability without flooding the mix with extra water.

- Early curing membranes: Apply curing compound as soon as finishing allows.

- Fog/mist finishing area: Maintain a thin moisture film during finishing, avoid direct water spray that weakens the surface.

Red Flags in Heat

Edges drying faster than the field; bleeding stops too early; finishers chasing the set. If you see crusting plus deep broom marks, your Concrete Installation is setting too fast.

Cold Slow Sets, Freeze Risk, Weak Surfaces

What Cold Does

Low temperatures slow hydration and can halt it below about 50°F (10°C). If in‑place concrete freezes before it reaches early strength, ice crystals disrupt the paste and permanently reduce durability.

Pro Tactics for Cold‑Weather Concrete Installation

- Warm materials: Use heated mixing water and protect aggregates from freezing.

- Accelerators (non‑chloride): Safely speed set without risking rebar corrosion.

- Insulation & enclosures: Blankets, temporary tents, or heated enclosures hold in heat.

- Extended curing: Keep concrete above the minimum temperature threshold for the first 48–72 hours.

- Delay saw‑cuts prudently: Don’t saw too early in cold conditions, watch strength gain.

Red Flags in Cold

Bleed water lingering for hours, a dusty surface the next day, or faint footprints after finishing. These signs point to under‑cured Concrete Installation with low early strength.

Wind The Invisible Finish Killer

Even on mild days, wind accelerates evaporation. A 10–15 mph breeze can turn a good pour into a crack‑prone slab. Combine wind with sun and low humidity, and you’ve got the classic recipe for plastic shrinkage.

Pro Tactics for Windy‑Day Placement

- Windbreaks: Temporary barriers reduce surface evaporation dramatically.

- Evaporation rate check: If rate > 0.2 lb/ft²/hr, deploy fogging and adjust schedule.

- Keep a tight finishing plan: Extra hands at strike‑off and bull float; no gaps between steps.

- Curing compound readiness: Spray as soon as the surface will take it without marring.

Humidity & Dew Point The Hidden Variables

Low relative humidity accelerates evaporation; high humidity slows it. Dew point matters at dawn and dusk, condensation on a warm slab can trap moisture at the surface and cause dusting or delamination.

Pro Tactics Around Humidity

- Read the sky: Track RH and dew point with a simple meter.

- Adjust start times: Pour after dew burns off; avoid night placements when condensation is likely.

- Balance evaporation: Use evaporation retarders judiciously; avoid over‑troweling.

Rain Timing Is Everything

Rain during placement washes out paste and ruins finish; rain just after finishing can pit the surface. On the other hand, controlled moisture after the initial set can aid curing.

Pro Tactics When Rain Threatens

- Tarp strategy: Stage tarps and pop‑up enclosures before trucks arrive.

- Edge protection: Protect slab margins first, they’re most vulnerable.

- Wait for the right window: If radar shows a short break, pause rather than risk a wash.

- Post‑rain checks: Remove standing water gently; don’t broom or trowel a rain‑etched surface.

Mix Design Tweaks for Weather Success

Water‑to‑Cement Ratio Discipline

Keep w/c in spec. Adding on‑site water to “loosen” a hot load weakens the slab and amplifies shrinkage.

Admixtures with Purpose

- Set retarders for heat; accelerators for cold (non‑chloride for steel).

- Water reducers to increase workability without extra water.

- Air entrainment for freeze‑thaw durability in exterior slabs.

Aggregate & Cement Choices

Optimized gradation reduces paste demand; SCMs (like fly ash or slag) can temper heat of hydration in hot weather. A good ready‑mix partner tailors the design to your Concrete Installation season.

Planning the Day A Weather‑Smart Workflow

1) Pre‑Pour Briefing

Confirm weather window, crew roles, saw‑cut timing, and curing method. Rehearse the hand‑offs, strike‑off, bull floating, edging, brooming, curing.

2) Site Prep That Pays

Control grades, compact subbase, and set forms tight. Stage windbreaks, shade, heaters, tarps, and curing compound so nothing is “on the way.” A clean, staged site is half of Concrete Installation success.

3) Placement & Consolidation

Place in manageable lanes, avoid segregation, and keep head pressure steady. Use internal or screed vibration as needed, don’t overwork the surface.

4) Finishing Windows

Watch the bleed: too soon and you trap water; too late and the surface tears. Keep tools clean; avoid steel‑trowel burn on exterior air‑entrained slabs.

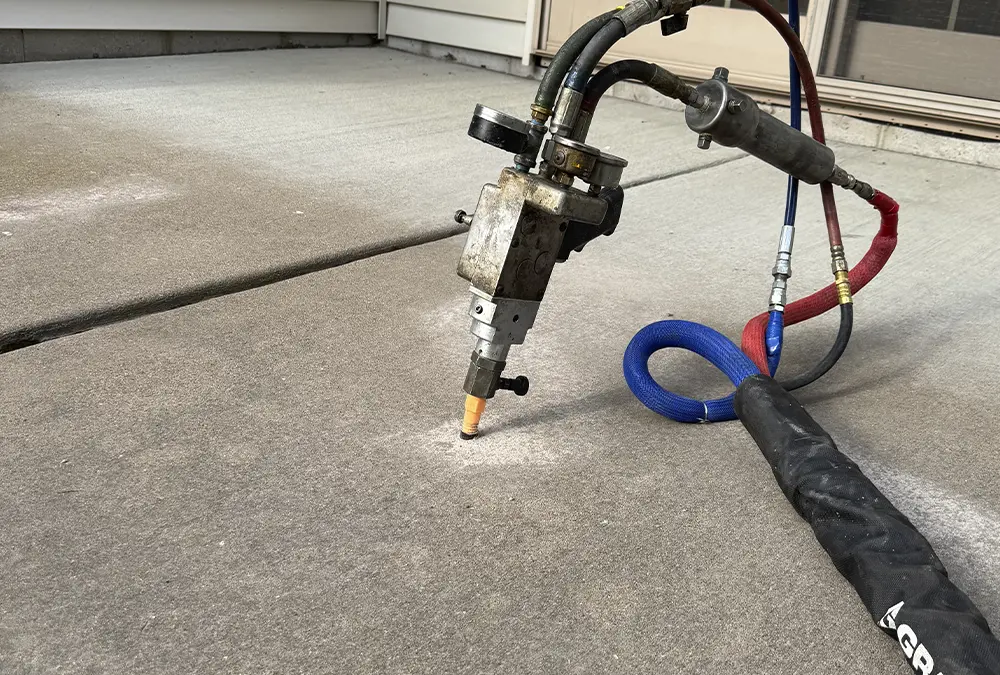

5) Curing That Actually Works

Membranes, wet coverings, or curing blankets pick one and commit. Maintain moisture and temperature for at least the first 3–7 days based on conditions. Great curing is the cheapest strength boost you’ll ever buy.

Seasonal Playbooks

Spring: Unpredictable but Powerful

Soils are wet, nights are cold, days swing warm. Leverage midday windows; watch wind. Extend curing and protect from late frosts.

Summer: Heat Management Mode

Start early, cool the mix, shade the slab, and cure fast. Saw‑cut on time, don’t let thermal stress find your weakest line.

Fall: Ideal for Strength if You Protect It

Stable days and cool nights favor quality, but sudden rain fronts demand tarp discipline. Keep blankets ready as temps drop.

Winter: Only with a Plan

Enclose small pours, heat the air and subbase, and monitor temps religiously for 72 hours. If you can’t meet minimums, reschedule your Concrete Installation.

Wind + Sun + Low RH The Triple Threat (Case Snapshot)

A driveway pour at noon in July, 86°F, 20% RH, wind at 12 mph. Evaporation spikes over 0.2 lb/ft²/hr. The crew deploys windbreaks, fogs lightly during bull float, uses a set retarder, and cures immediately after broom. Result: no plastic shrinkage cracks, clean texture, strong early strength.

Post‑Pour Care That Protects Your Investment

- Keep traffic off until design strength is reached or per finisher guidance.

- Seal joints and edges promptly; caulk control joints after saw‑cutting when specified.

- Divert downspouts and fix negative grades that dump water at slab edges.

- Schedule a 30‑day check for surface dusting, curling, or random cracking address early.

Choosing a Contractor Who Plans for Weather

Look for pros who bring a weather plan to the bid, not after problems appear. They should discuss curing, enclosures, admixtures, and saw‑cut timing in plain language and put it in writing. That’s the difference between a one‑season slab and a decades‑long performer.

Ready for a Weather‑Smart Build?

When your project can’t afford a do‑over, partner with a team that treats weather as a design input, not an excuse. From mix design to curing, you need a coordinated plan that adapts to real‑world conditions and protects your schedule and budget.

Contact us for a complete Concrete Installation. We design, place, and cure with Minnesota’s climate in mind, so your slab looks better and lasts longer.

For engineering‑grade guidance on concrete in adverse weather, see the American Concrete Institute resources.