Concrete in Minnesota faces unique seasonal stress, and Concrete surfaces near Minneapolis Saint Paul endure some of the widest temperature swings in the country. When winter arrives, meltwater penetrates small pores and joints. As it refreezes, it expands with surprising force and begins to separate slabs from their base. That cycle repeats dozens of times per year, which is why homeowners see gaps, rocking steps, and uneven sidewalks. Addressing those symptoms early with Polyjacking preserves structure, reduces liability, and keeps curb appeal high even after harsh winters.

Understanding freeze thaw mechanics in northern climates

The physics behind freeze thaw damage explains why Concrete fails at the surface and the subgrade first. Water travels downward through hairline cracks, fills voids around aggregate, and expands when temperatures drop below freezing. That expansion exerts pressure greater than the tensile capacity of typical residential mixes. Over time the paste and subbase loosen, the slab loses contact with compacted soil, and differential settlement begins. Minneapolis Saint Paul experiences frequent cycles around 32°F, which magnifies the problem and accelerates the need for Polyjacking to restore support.

Microcracking and pore saturation in slab systems

This subtopic introduces how pore structure, air entrainment, and saturation levels influence durability in Concrete exposed to winter. Properly entrained air creates tiny chambers that accept expanding water and relieve stress, but older driveways and walks often lack this feature. When pores saturate during shoulder seasons, every quick drop to freezing adds microcracks that spread laterally. That hidden network explains why a slab can look intact yet rock underfoot after a storm.

Repeated cycles drive water deeper and widen existing fissures in Concrete until they connect voids beneath the slab. As soils wash out, the panel separates from its base and begins to move. That motion invites more infiltration because joints open and sealants fail prematurely. The answer is to reestablish continuous support with Polyjacking, which fills cavities, blocks water paths, and stabilizes panels without demolition. Once the base is consolidated, surface sealing becomes effective again and seasonal movement declines.

Stresses are not uniform across every Concrete panel, and edges near downspouts or plow lines take the brunt of expansion. Cold air attacks corners first, concentrating tensile demand where reinforcement is sparse. With each refreeze, the slab curls slightly and gaps appear at the apron. Freeze infiltration finds those gaps and repeats the cycle. Strategic injection points during Polyjacking target these weak zones, re bonding the underside to a supportive foam base that resists renewed washout.

Soil loss void formation and differential settlement

This subtopic explains how subbase erosion follows downspout discharge patterns and how Concrete loses bearing. Granular soils migrate with every spring melt, leaving open pockets that the eye cannot see. Vehicle loads then flex the slab, compacting remaining soils unevenly and introducing more gaps at mid panel. Without timely intervention, the center sags and adjoining joints become trip hazards.

When the underside is no longer supported, Concrete begins to echo under footfalls and shows rocking at the edges. That is the ideal moment for Polyjacking, which flows as a liquid to chase voids before expanding into a rigid, closed cell foundation. The material resists moisture, stops pumping under traffic, and adds insulation that moderates freeze thaw gradients beneath the slab. With the base restored, the surface accepts sealers better and protection lasts longer between maintenance cycles.

Homeowners often assume a full replacement is the only option when Concrete drops an inch or two, yet the structural body of the slab can remain sound. Injecting Polyjacking foam restores elevation with precision, reduces future water paths, and avoids the prolonged cure time of fresh placement. The result is an immediate return to use, less disruption to landscaping, and a smaller carbon footprint compared to removal and haul away. That speed makes Thaw season an opportune time to correct winter damage before summer traffic.

Why polyjacking is the right tool for freeze thaw damage

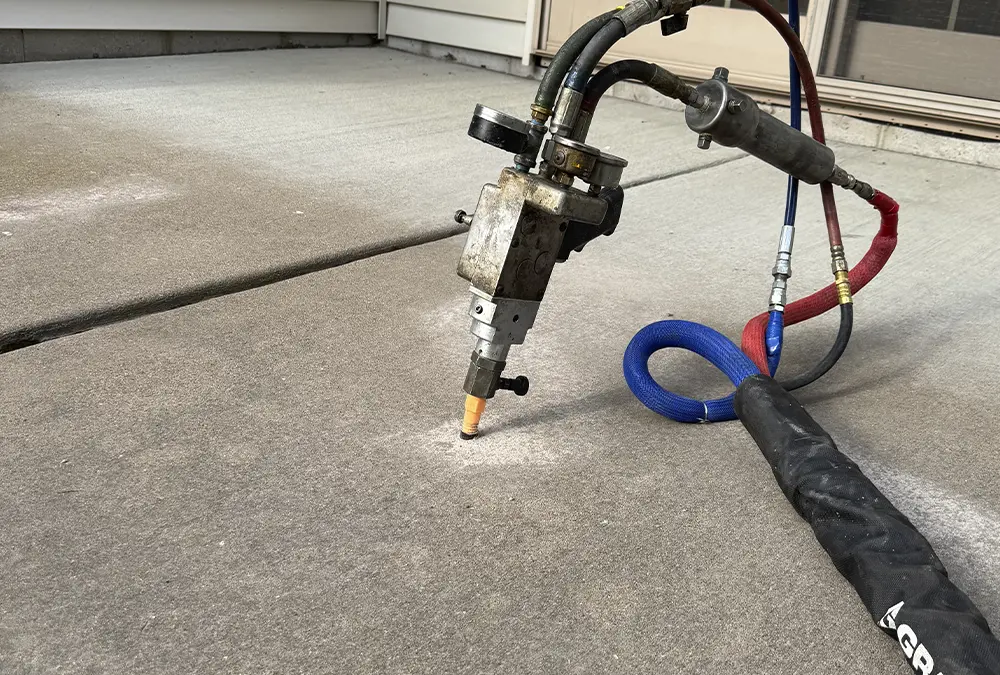

Choosing the right repair method requires evaluating water resistance, speed, and longevity in cold climates where Concrete must endure daily thermal swings. Polyjacking excels because the closed cell foam is hydrophobic and will not absorb meltwater, so it preserves lift and support as seasons change. The process uses small injection ports that minimally impact appearance. Because it cures rapidly, sidewalks, aprons, and steps return to service in hours, not days, reducing liability where public foot traffic is common.

Hydrophobic chemistry and long term stability benefits

This subtopic introduces why polymer chemistry performs in saturated soils and how it interacts with Concrete substrates. Closed cell structure rejects liquid water and slows vapor transfer through the base, limiting the volume that can freeze below the slab. That barrier effect helps maintain consistent support under thermal cycling. Adhesion at the interface reduces micro movements that otherwise grind at aggregate and widen joints.

When Polyjacking expands, it distributes pressure across broad areas rather than point loading the panel. That uniform support keeps Concrete flatter during Freeze Thaw transitions that would otherwise telegraph as new cracks at the surface. Because the foam remains dimensionally stable through typical residential temperature ranges, seasonal changes do not undo the correction. After lift, resealing the surface and resetting drainage ensures the system works as a whole and extends service life.

Durability is also about resisting washout during heavy spring storms. Hydrophobic foam keeps bearing even when runoff tries to re enter pathways under Concrete. That means the same voids are not re created, breaking the annual cycle of patching. With the base locked in, homeowners can focus on joint maintenance and downspout extensions rather than repeating structural repairs. The long term savings make Polyjacking an investment rather than a temporary fix.

Precision lifting for steps walks aprons and garage floors

This subtopic introduces how controlled injection patterns produce smooth transitions and ADA friendly results for Concrete paths. Crews map voids, set target elevations, and work from the low edges toward the highest points to avoid creating tension across panels. Incremental lifts of a fraction of an inch are confirmed with levels as the foam expands. That measured approach preserves slab integrity while eliminating trip hazards.

Because Polyjacking requires only small ports, patching blends cleanly, and the restored Concrete is ready for foot traffic almost immediately. Driveways and aprons typically accept vehicles the same day, minimizing routine disruption. The process suits tight urban lots as well as larger suburban sites, and it performs in confined spaces like garage interiors. By restoring the original plane of the slab, doors seal properly, snow melt drains away, and ice formation declines at thresholds.

Homeowners also appreciate that Polyjacking reduces excavation near landscaping. Shrubs, edging, and pavers remain in place while the underlying Concrete regains support. That surgical footprint limits collateral damage and preserves property value. In neighborhoods that value neat presentation, the quick transformation after Thaw is visible in a single afternoon, which makes scheduling convenient before summer events.

Local applications and seasonal planning across the Twin Cities

Minnesota neighborhoods demand year round strategies that protect Concrete through repeated freeze thaw cycles. Eagan, Apple Valley, and Burnsville see early snow and late cold snaps, so timing matters when planning repairs. Polyjacking works well in shoulder seasons when soils are accessible and the base is not deeply frozen. That window allows crews to track drainage patterns and seal joints while weather cooperates. Coordinating repair with gutter and grading adjustments multiplies results.

Driveways sidewalks and pool decks under northern weather

This subtopic introduces typical residential locations where Concrete suffers from plow abrasion, deicing salts, and runoff concentration. Driveways experience ruts near the apron as packed snow melts and refreezes. Sidewalks settle near downspouts where splash erosion is constant. Pool decks show hollow sounds after spring opening as washout under corners becomes apparent. Each of these surfaces benefits from targeted Polyjacking that closes gaps before heavy use returns.

After lift and stabilization, owners should reseal joints and edges so Concrete resists water entry during the next Freeze cycle. A breathable, penetrating sealer protects the top surface while allowing moisture to escape. Downspout extensions move discharge five feet from the slab, and regrading gradients keep runoff moving. By combining structural support with surface protection, the system withstands hard winters better, and maintenance becomes predictable instead of reactive.

When neighbors see smooth transitions and reduced puddling, they often schedule their own repairs, which is common in HOA communities. Polyjacking scales well across multiple Concrete panels because injection points are efficient and cleanup is minimal. For public walks, maintaining even joints helps meet accessibility expectations and reduces liability. The result is safer routes for mail carriers, students, and evening walkers even during Thaw periods when ice can reform overnight.

Commercial entries ramps and warehouse slabs

This subtopic introduces how retail and light industrial sites manage settlement and keep Concrete access ways compliant. Entrances require tight tolerances to avoid door drag, and ramps need smooth transitions for carts and wheelchairs. Warehouse interior slabs carry repetitive loads where a rocking panel quickly grows into a safety issue. Polyjacking targets voids with minimal disruption to customers and shifts.

Because business continuity matters, crews stage injection to reopen lanes progressively while foam cures. That approach returns Concrete to service the same day in most cases, which is valuable during retail hours. Managers can then implement maintenance protocols for joints and seals so water does not re enter. Over time, the stabilized base cuts patching budgets and keeps operations predictable through Freeze Thaw swings.

For property managers, documentation of elevations before and after lift supports planning and budgets. Photos and level readings demonstrate improved drainage away from thresholds. Those records pair well with seasonal checklists that include gutter cleaning, snow storage planning, and surface sealing. With Polyjacking established as the structural solution, routine care keeps Concrete looking clean and performing reliably.

Process best practices for reliable results

Effective results come from a disciplined workflow that identifies causes, corrects structure, and manages water around Concrete long after the work is complete. Polyjacking is one part of a broader plan that includes sealing, drainage, and traffic management. Homeowners and managers get the best value when they bring all three elements together in a single visit. That synergy keeps winter expansion from reopening paths beneath the slab.

Assessment planning and target elevations

This subtopic introduces the pre lift steps that ensure precise outcomes for Concrete surfaces. Crews inspect joints, downspouts, and grade to map where water concentrates. They note hollow sounds and rocking edges, then set reference heights for doors, aprons, and adjacent panels. With a shared plan, technicians drill compact ports on a grid that reflects the void map and structural needs.

Injection follows a sequence that avoids trapping stress. Foam is introduced in small quantities, allowing Polyjacking expansion to fill cavities gradually and confirm results with levels. As the base increases in rigidity, the panel rises uniformly and contacts supporting soils again. That careful rise protects Concrete from bending stresses and keeps hairline cracks closed rather than widening under lift.

The plan concludes with patching ports and finishing surfaces to blend with existing textures. Teams verify slopes toward drainage paths so water moves away on the next Thaw day. A final walkthrough sets expectations for joint sealing and surface protection. With measurements documented, owners can compare movement after storms and confirm the stability achieved by Polyjacking.

Water management sealing and seasonal maintenance

This subtopic introduces post lift practices that keep Concrete protected. Joint sealants block intruding water at the most vulnerable points while penetrating sealers reduce surface absorption. Edging soil and adjusting gutters direct meltwater toward lawn or drains. Where plows operate, adding markers prevents blade strikes at slab edges, which keeps joints intact longer.

Seasonal checkups after major Freeze events make small corrections easy before they grow. Reapplying sealers at manufacturer intervals keeps the surface resilient through Thaw cycles. Cleaning deicing residue reduces chemical attack and preserves the top paste that guards against abrasion. Those simple steps amplify the structural benefits of Polyjacking and extend the time between interventions.

Coordinating with neighbors or property managers builds consistency across connected Concrete panels. When one section drops, it can stress the next. Addressing settlement holistically prevents a domino effect and preserves uniform grades for drainage. With a stable base and controlled moisture, the freeze thaw engine that once lifted and dropped panels loses leverage.

Costs timelines and value for cold climate homeowners

Budget planning matters when selecting a repair approach for Concrete in a northern climate. Replacement requires demolition, hauling, formwork, new placement, and a cure period before use. Polyjacking avoids most of that process, delivering speed and reducing waste. While each site varies, homeowners commonly find the overall cost compares favorably with replacement once downtime and landscaping impacts are included.

Price variables site conditions and scope

This subtopic introduces the inputs that guide estimates for Concrete lifting. Total square footage, number of panels, depth of voids, and access affect the injection plan. Heavily washed out bases require more material, while confined spaces call for additional time. Drainage corrections and joint sealing are often bundled to lock in gains and reduce future water entry.

Accurate assessments keep expectations aligned and help prioritize panels. Crews can lift the most critical Concrete first to remove hazards, then stabilize adjacent sections for uniform appearance. That staged approach fits seasonal windows and spreads investment sensibly. Because Polyjacking is efficient, many projects fit comfortably into a single day with immediate return to use.

Owners appreciate that avoided demolition also avoids surprises under landscaping. Sidewalks near gardens and aprons near decorative rock can be preserved. That gentler footprint keeps overall value high while providing the structural outcome the site needs. With Polyjacking in place, the repaired Concrete presents clean lines and sheds water effectively through future Freeze Thaw events.

Aftercare maintenance and long term performance

This subtopic introduces the routine tasks that protect Concrete after repair. Sweeping debris away from joints, keeping gutters clear, and directing downspouts are simple habits that prevent saturation. Resealing at scheduled intervals keeps absorption low so ice has fewer footholds. Watching for early signs like rocking corners helps owners call for help before gaps widen.

Because Polyjacking foam is closed cell and hydrophobic, it resists water and maintains bearing even when soils are wet. That stability keeps Concrete aligned through seasonal swings. Homeowners notice less puddling at aprons, tighter door seals, and fewer icy patches at entries. The property stays safer for family and visitors.

With structure stabilized, future work becomes cosmetic rather than structural. Cleaning and resealing produce a refreshed look, and maintenance checks become predictable. In neighborhoods across the Twin Cities, that reliability is why owners choose Polyjacking after tough winters and why their Concrete continues to perform when temperatures jump above and below freezing in a single day.

Call to action and next steps

If winter left your Concrete uneven or hollow sounding, schedule an evaluation to secure the base before the next storm. A quick visit identifies voids, maps a lift plan, and confirms drainage corrections that keep water out. The combination of targeted Polyjacking, joint sealing, and seasonal maintenance stops recurring problems and restores smooth, safe access around your home. Protect your investment and get ready for the next Thaw with a clean, level finish.

Polyjacking keeps projects fast clean and reliable all year. For questions or to request a quote, please contact our team today.