Everything You Need to Know Before Starting the Job

Uneven concrete floors are more than just a visual problem — they can lead to structural issues, flooring installation failures, and water drainage complications. Whether you’re preparing for tile, hardwood, vinyl, or epoxy, knowing how to level a concrete floor is essential.

This guide walks you through the entire process, including materials, preparation, and professional tips to ensure lasting results.

Tools and Materials Needed to Level a Concrete Floor

Before getting started, gather the following:

-

Leveling compound or self-leveling concrete

-

Primer for concrete surfaces

-

Trowel or gauge rake

-

Concrete grinder or sander (for high spots)

-

Vacuum or shop vac

-

Mixing bucket and paddle

-

Protective gear (gloves, goggles, mask)

Optional but useful tools:

-

Long straightedge or screed

-

Moisture meter

-

Knee pads

Step 1: Evaluate the Floor for High and Low Spots

Use a straightedge or laser level to identify problem areas

Start by checking the entire floor using a 6–10 foot straightedge, laser level, or digital level. Move across the floor and mark areas that dip below or rise above the desired flatness. Most manufacturers allow a maximum variation of 1/8 inch over 10 feet for flooring installation.

If high spots are minimal, you might be able to grind them down. For larger dips or widespread unevenness, self-leveling compound is the most efficient solution.

Step 2: Clean and Prep the Surface Thoroughly

Remove dust, debris, oils, and old adhesives

A clean surface is essential for proper adhesion. Use a shop vac to remove all dust and particles. For greasy or waxy residues, apply a degreaser and rinse thoroughly. If there’s old glue, paint, or sealant, remove it with a concrete grinder or stripper.

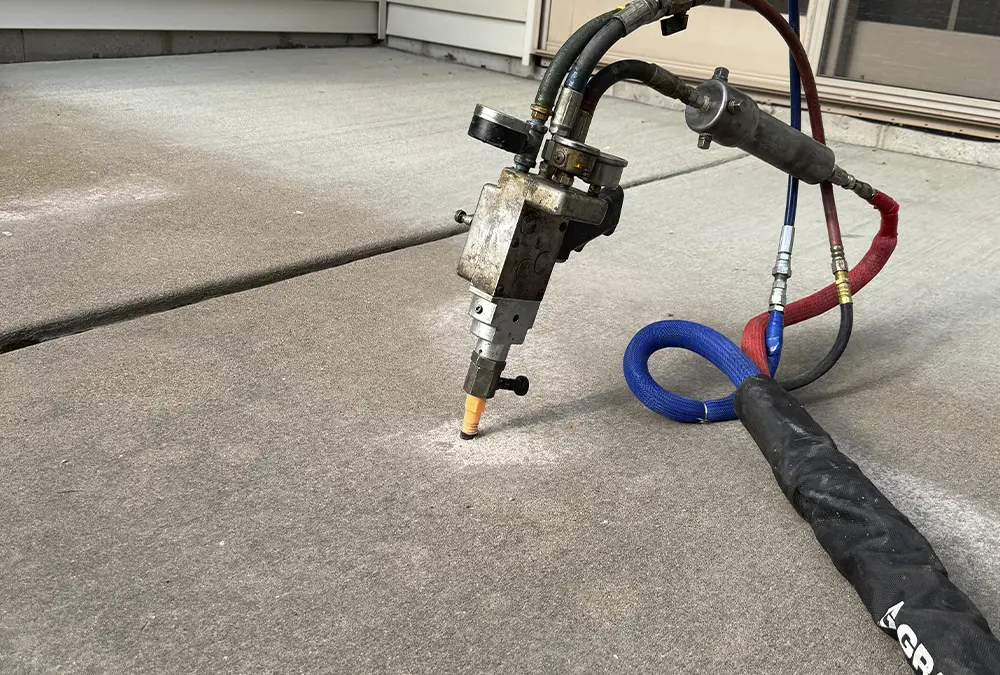

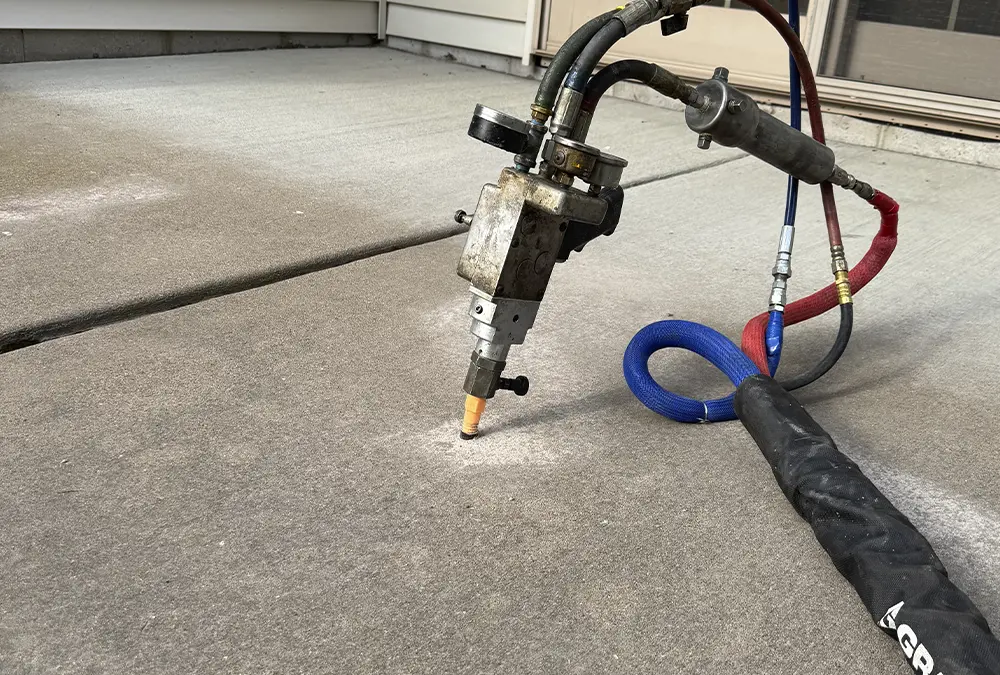

Important: If your concrete has any cracks or control joints, seal them with concrete filler before continuing.

Step 3: Apply Primer to Help the Leveling Compound Bond

Priming improves adhesion and prevents rapid absorption

Use a floor primer designed for concrete and apply it according to the manufacturer’s instructions. Most primers need to dry for a minimum of 1 to 3 hours. Don’t skip this step — it ensures that the self-leveling compound sticks evenly and reduces the chance of future cracks or bubbles.

Step 4: Mix the Self-Leveling Compound Properly

Follow mixing instructions precisely to get the right consistency

Use a large mixing bucket and a drill-mounted paddle mixer to combine the compound with water. Most self-leveling products must be poured immediately after mixing, so work quickly and in sections.

Do not over-mix or under-mix. The ideal texture is a pourable consistency that can spread easily but won’t separate or set too fast.

Step 5: Pour and Spread the Compound Evenly

Work in sections and move fast — the compound sets quickly

Pour the leveling compound starting from the lowest point and use a gauge rake or trowel to spread it evenly. Let gravity do much of the work, but assist where necessary to ensure smooth coverage.

For large areas, consider asking a second person to help with mixing while you pour. Keep foot traffic off the floor until it’s fully cured — usually 24 to 48 hours, depending on the product and environment.

Step 6: Sand Down Any Minor Imperfections

After curing, sand lightly for a flawless finish

Once the surface is dry and hard, inspect for minor ridges or trowel lines. Use a concrete sanding pad or pole sander to smooth any rough spots.

Now your concrete floor is flat, smooth, and ready for any type of final flooring — whether tile, vinyl planks, carpet, or epoxy.

Common Mistakes to Avoid When Leveling Concrete

-

Skipping the primer leads to poor adhesion.

-

Not addressing moisture can cause the compound to delaminate.

-

Over-watering the mix weakens the compound and creates shrinkage.

-

Pouring without planning work in logical sections to avoid cold joints.

-

Ignoring room temperature cold slows curing; heat speeds it up too fast.