Polyjacking restores smooth entries where the driveway meets the garage, eliminating the sharp lips and hollow spots that snag tires and collect winter slush. In the Twin Cities, repeated freeze thaw cycles and seasonal runoff wash fines from the base under the apron, lowering the slab just enough to create a daily annoyance. With precise, hydrophobic foam lifts that work through small injection points, Polyjacking closes the gap, protects door thresholds, and keeps snow melt flowing the right way. The upgrade feels immediate the next time you pull in—no bump, no scrape, just a clean glide into the bay.

Why garage aprons sink and how Polyjacking reverses the pattern

Garage aprons sit at the front line of weather and traffic. Plow piles line the edge, downspouts discharge nearby, and vehicles hit the same track every day. Water finds tiny joints and carries away fine material, leaving small voids that a glance can miss but a wheel can feel. Over time, the apron separates from the driveway or from the interior slab, creating a lip. By restoring continuous bearing beneath the panel, Polyjacking ends the pumping action and brings the surfaces back into alignment.

Moisture paths soil loss and day to day loads

This overview frames how routine conditions create settlement at the apron. Runoff concentrates at low spots near the threshold and pushes fines toward the street. Tires magnify the effect as they bounce over the same edge morning and night. With each pass, the slab flexes, the base loosens, and contact fades. The joint opens enough to let more water in, and the cycle accelerates until the lip becomes obvious and the drop catches tires.

A disciplined lift interrupts the cycle by filling voids in liquid form and expanding into a rigid, closed cell support. With Polyjacking, the foam resists moisture and stays put under traffic, so the base stops moving. As the panel reconnects to firm support, the joint closes and edges stop chipping. The clean transition protects door seals and reduces drafts that creep in during cold snaps, making the entry feel tighter and more comfortable.

When the base is unified, simple maintenance like resealing joints and directing downspouts away from the edge works much better. Water travels along the intended slope instead of into gaps, keeping the apron stable through storms and thaw days. The driveway looks the same, just smoother, and the benefit shows up every single time you park.

Freeze thaw cycles curb lines and corner stress

This overview explains why winters in Minneapolis Saint Paul are hard on aprons. Temperatures cross the freezing point often, expanding any water in the pores and joints. If support is uneven, that expansion pries edges upward while washout drops the center. Corners by the curb take the worst of both worlds—cold air and meltwater—so small cracks open and chips appear. Once a few edges loosen, every plow pass or wheel turn exaggerates the problem.

Targeted Polyjacking counters those forces by restoring uniform bearing across the slab. Incremental lifts of a fraction of an inch align the apron with the driveway and the garage floor without bending the panel. Small, tidy injection ports patch flush, blending with the existing surface. The result is a joint that feels quiet under tires and sends water toward the gutter instead of into the gap.

Because the foam is hydrophobic and closed cell, it resists re saturation during spring storms. That stability means the fix holds through seasonal swings, so you do not chase the same defect year after year. The smooth rollout also protects snow shovels and plow blades from catching at the threshold.

Advantages you feel every time you park

Choosing Polyjacking for aprons is about daily comfort, reduced wear, and a cleaner look. The work happens quickly with minimal disruption, and the improvement is immediate. Doors seal better, puddles shrink, and the approach feels natural again.

Faster return to service tidy workflow and precise alignment

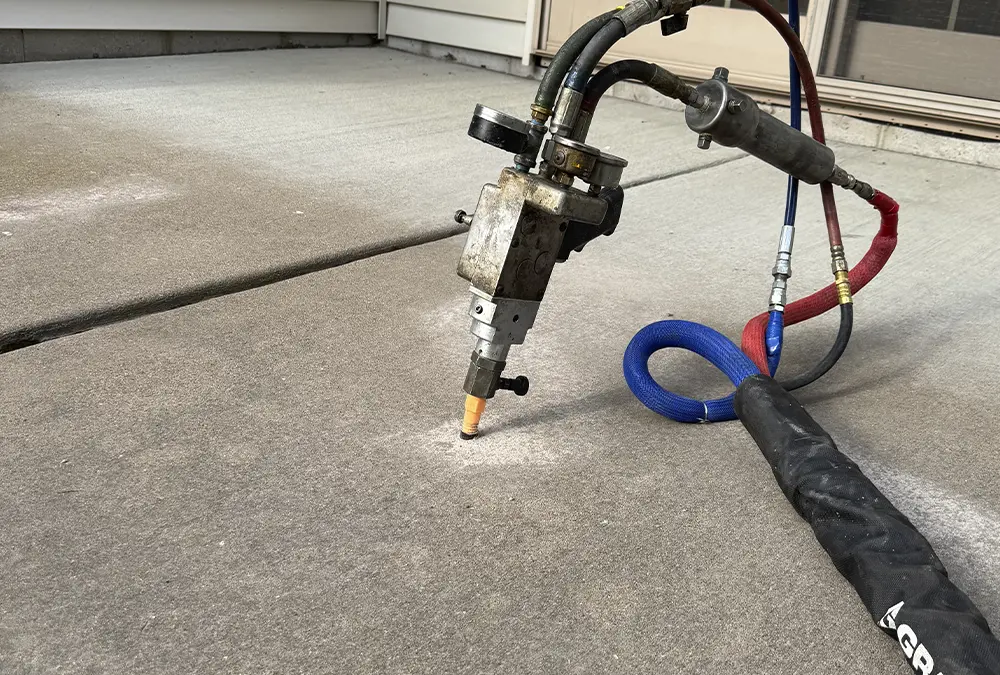

This overview shows how the method fits busy schedules. Crews map voids, set target elevations, and work from low edges toward the highest points to avoid stress at cracks. Injection proceeds in small steps confirmed by levels and straightedges. Because Polyjacking cures quickly, most entries return to use the same day, keeping routine life on track.

The site stays neat. Compact equipment and small ports limit dust and debris, and patching blends with surrounding textures. Neighbors see improvement rather than construction, and landscaping near the apron remains untouched. The project reads as careful maintenance that elevates curb appeal.

Precision matters at thresholds where doors meet floors. With measured lifts, seals stay uniform, and weatherstripping sits correctly. The straight, even line across the apron becomes part of the home’s finished look and a subtle daily convenience.

Smoother driving reduced wear and safer footing

This overview connects smooth aprons to comfort and longevity. Wheels roll without a thud, suspensions avoid sharp shocks, and the steering stays steady as you enter. Those small differences protect tires, bearings, and garage door hardware. Inside, fewer puddles form at the threshold, reducing icy patches in winter and slippery spots in shoulder seasons.

For families and guests, the safer step across the threshold matters in all weather. Strollers, carts, and bikes transition without catching a lip. The quiet ride sets the tone for the whole entry experience—easy in, easy out.

Over months and seasons, the gentler contact saves wear on the concrete itself. Edges stop chipping and joints hold sealant longer. The apron becomes a reliable part of the driveway system rather than a recurring repair.

Local planning and seasonal timing that work in the Twin Cities

Weather drives schedules in Minnesota, but there are windows in every season where Polyjacking performs well. Planning around temperature and moisture keeps outcomes consistent and avoids rush decisions.

Spring and early summer windows after thaw

This overview explains why the months after thaw are ideal. Crews can observe where meltwater traveled and correct the structural cause before heavy summer use. With soils accessible and temperatures moderate, Polyjacking flows well and binds uniformly to the base. Joint sealing added after lift lasts longer because panels stop moving.

Early repairs also support summer projects—coatings, edging, and driveway maintenance—by providing a stable, level surface. The entry looks refreshed when outdoor life is at its peak, and wear patterns set up cleanly for the year ahead.

The same window works for minor grading and downspout adjustments that keep water away from the threshold. Small tweaks make a big difference when the structure is already sound.

Late season strategy before deep freeze

This overview covers planning lifts before winter arrives. When nights are cool but days still soften the surface, Polyjacking can close gaps and restore slope so meltwater drains properly. Curing blankets and short closures protect patches, and doors resume normal use quickly. Fixing the lip before the first big snow prevents plow blades and shovels from prying it open again.

If a sudden cold snap follows a warm spell, work pauses and protection stays in place overnight. Flexibility preserves quality and ensures the apron is ready for the long freeze ahead. A tidy joint going into winter means fewer icy ridges where tires compress slush at the threshold.

In either window, the payoff is a clean transition that holds up through the season.

Process best practices that deliver durable aprons

Reliable results follow a careful sequence—diagnose the cause, restore structure, and manage water. Polyjacking is the structural fix, and a few small habits keep it working for years.

Mapping voids sequencing lifts and protecting thresholds

This overview details the on site routine. Technicians listen for hollow zones, chalk low edges, and set reference heights at the door and along the curb. Holes are placed to chase known cavities and avoid utilities. Lifts proceed slowly so the apron rises uniformly and meets the driveway without creating new stress.

As the base re establishes contact, joints close and the panel sits firmly again. Ports are patched and blended, and slopes are verified toward the street. A quick door test confirms smooth seals and alignment. The careful pace protects the slab and the finishes that touch it.

Photos and level readings document the result for your records. That transparency supports future maintenance planning and gives confidence that the entry is truly set.

Managing water routes joints and seasonal maintenance

This overview ties structural gains to simple care. Sealing joints after lift blocks water at the most vulnerable lines, and redirecting downspouts keeps the threshold dry. Where snow storage piles up, a small shift in placement protects the repaired edge. In spring, a light rinse clears fine grit that can act like sandpaper near the joint.

These habits are easy to keep and pay off during storms. With water moving away from the entrance, the base stays dry and stable. The apron remains aligned, and the smooth approach becomes the new normal.

Routine checks after major weather remind you to nudge gravel or soil if runoff patterns change. Small adjustments maintain a big improvement.

Coordinating with adjacent scopes for a complete entry upgrade

An aligned apron makes everything around it work better. Doors close cleanly, coatings last longer, and nearby slabs cooperate. Aligning timelines with other small projects amplifies the result and keeps the entry looking sharp.

Door adjustments coatings and driveway care

This overview shows how small finishing touches complement Polyjacking. If a door sweep needs a quick reset, it happens right after the lift. Where homeowners plan to seal or coat the driveway, a stable apron prevents telegraphing cracks and uneven wear. Edging looks straighter against a smooth line, and landscaping reads more polished.

Housekeeping becomes easier too. Snow blowers and brooms glide over the joint without catching, and spring cleanup runs faster. The visual payoff makes the home feel cared for from the street to the bay.

For larger future changes—new surface treatments or layout tweaks—the stable base is step one. With structure set, cosmetic upgrades deliver full value.

Working alongside trades and minor repairs

This overview covers coordination that keeps projects efficient. If a threshold heater, sensor, or seal needs attention, the best moment is right after Polyjacking when alignment is true. Minor concrete touch ups proceed on a steady substrate, and any small paver accents set cleanly against the fresh line.

If an adjacent panel is too compromised to lift, documentation helps plan a clean Replacement later. Most entries fall well within the lift range, but having a plan for exceptions prevents surprises.

When walkways meet the apron at angles, exterior Leveling and Lifting of nearby panels may be considered so every path meets smoothly. A unified approach keeps movement consistent and edges tight.

Gentle close for the season

You notice the improvement every time the garage door opens. With measured lifts that restore support and slope, Polyjacking removes the jolt at the threshold and keeps water moving the right way. Combine the structural fix with simple joint care and mindful drainage, and the entry stays smooth through storms and summers alike. Contac us when you are ready to refresh the daily drive in, we are here to map the steps and make the process simple from start to finish.