Mudjacking inside a home or facility calls for a different playbook than outdoor lifting. Interior slabs sit near walls, utilities, finishes, and occupants, so planning must go deeper on dust control, noise, injection layout, and post lift protection. When homeowners and managers understand how access, ventilation, and mix management work together, results feel seamless and spaces get back to normal fast. With a measured approach that respects structure, air quality, and finishes, Mudjacking can correct settlement under basements, utility rooms, foyers, and warehouse interiors with confidence.

Why interior lifting demands a specialized plan

Indoor environments add constraints that change how crews stage equipment and how mixes are delivered. Door widths limit access, HVAC systems can spread dust, and finished flooring may surround the target slab. The key is a workflow that contains mess, protects adjacent materials, and restores elevations without transmitting stress into framing or finishes. With thoughtful sequencing, Mudjacking becomes a precise interior service rather than a disruptive construction project.

Pre assessment mapping and risk controls

This overview introduces the survey steps that reduce surprises before a single hole is drilled. Technicians map voids with tapping and levels, note crack patterns, and check for hollow sounds that betray separation from the subbase. They identify load lines near walls, posts, and stair footings, then plan an injection grid that supports the panel evenly. Utilities are located and marked so ports avoid radiant tubing, conduits, or in floor drains.

A protection plan follows. Returns and supplies on the HVAC system are covered near the work zone so dust does not travel through the home. Doorways receive zipper barriers for access, and a negative air machine or simple box fan pushes air out through a window when possible. With containment in place, Mudjacking proceeds with confidence and minimal disturbance to the household.

When finishes surround the target slab—baseboard, cabinets, or thresholds—crews measure clearances and plan lifts in fractions of an inch. The strategy preserves trim lines and avoids binding doors as elevations change. A shared checklist with the owner sets expectations and confirms where items will be moved or protected before work begins.

Access staging ventilation and occupant comfort

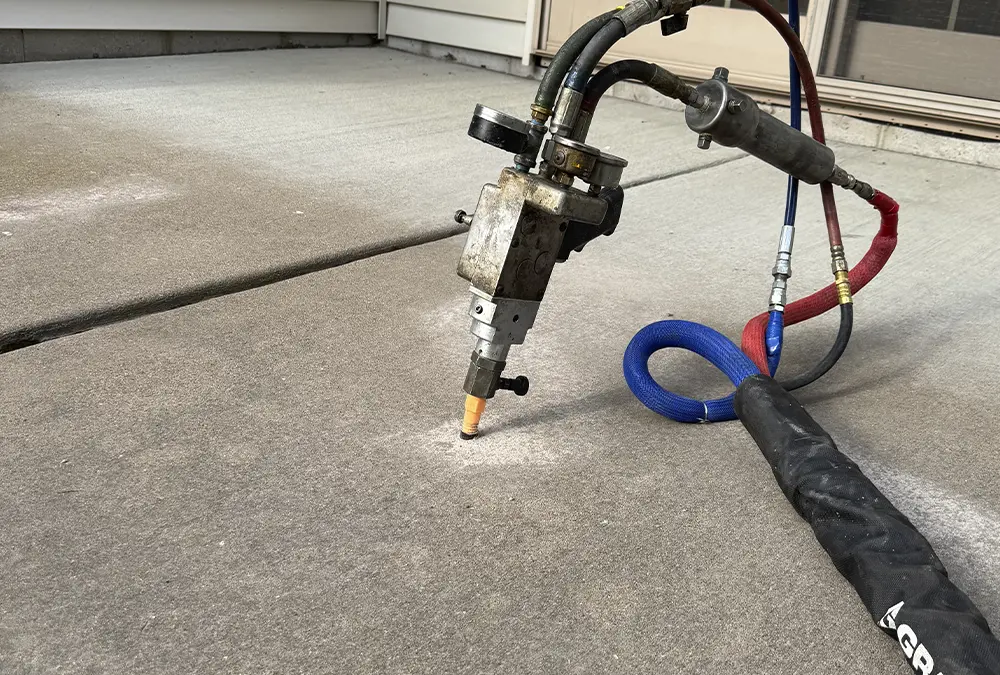

This overview covers the logistics that make indoor work smooth. Equipment is staged on mats that protect floors and distribute loads. Hoses and cords are routed along walls and taped at crossings to prevent trips. A small mixing area is set near an exterior door to shorten travel and keep water and cement away from living areas. Where weather allows, exterior mixing further reduces indoor exposure.

Ventilation is addressed early. Fans establish a gentle flow out of the space, supporting comfort and clearing light odors associated with slurry handling. Noise is scheduled around family routines or office hours, and technicians provide a simple timeline so occupants can plan quiet periods. With expectations clear, Mudjacking moves quickly and calmly.

Communicating about pets, kids, and sensitive items helps everyone relax. Gates, crates, or closed rooms keep curious companions safe, and temporary coverings protect furniture in the path. These small courtesies turn a technical procedure into a considerate service experience.

Structural considerations for interior Mudjacking

Inside, the slab’s relationship to walls, posts, and doors is more intimate. Lifts must restore plane while avoiding undue stress on finishes or frame members. Precision and patience produce the best outcomes.

Load paths joints and isolation from walls

This overview explains how slabs interact with surrounding structure and why injection patterns matter. Many interior slabs are floating—poured inside perimeter foundations with isolation joints at walls. Others may bear partially on grade beams or haunches. Crews confirm the slab type and decide how to re establish support under the center first, then trim edges so the plane meets thresholds and adjoining rooms.

Working from low areas outward, small lifts keep tension from building at isolated cracks. As Mudjacking restores contact beneath, joints remain tight rather than prying apart. Where expansion foam strips or fiberboard were installed at walls, technicians monitor for contact and stop lifts before compression risks telegraphing into drywall or tile. The aim is a flat, quiet slab that carries loads without pushing on finishes.

Door clearances and appliance alcoves receive special attention. A few millimeters of rise can affect swing and fit. Incremental measurements at these points keep function intact while stability returns underfoot.

Utilities radiant heat and in floor features

This overview highlights hidden elements that shape injection strategy. Radiant heat loops are common in basements and garages; crews scan or consult plans to avoid tubing. In floor drains, cleanouts, or sump pits must remain pitched to function. Lifts occur around these features with target elevations that preserve flow toward drains and keep traps primed.

Where conduit stubs or rebar chairs are present, hole placement shifts to avoid obstructions. The slurry’s path is encouraged toward voids, not along rigid inclusions that could create hard spots. With careful mapping, Mudjacking supports the slab like a uniform mattress rather than a series of isolated piles.

Cabinet toe kicks, islands, and built ins also influence strategy. Small adjustments can preserve level countertops and keep hardware aligned when floors rise slightly. Pre checks ensure that tiny changes enhance rather than disturb the finished space.

Mix design cleanliness and indoor-friendly workflows

Interior work raises the bar on cleanliness and consistency. Tight control of temperature, water proportion, and delivery distance keeps behavior predictable and the jobsite tidy.

Batching temperature control and placement rhythm

This overview details how crews keep mixes cooperative indoors. Heated mixing water maintains workable viscosity so the slurry flows to remote voids without segregation. Batch sizes match the pace of drilling and injection; smaller, more frequent batches reduce wait times and prevent material from cooling on the way in.

Placement follows a steady rhythm—inject, observe, verify with levels, then cap and wipe. Keeping ports clean as you go avoids raised patches that require aggressive grinding later. With consistent behavior, Mudjacking re establishes a continuous base that feels solid under footfall and resists movement when appliances roll back into place.

Documentation of water temperatures and batch times supports quality and provides owners a clear record of the process. That transparency pairs well with the professionalism expected indoors.

Dust control surface protection and cleanup sequence

This overview lays out simple habits that keep interiors spotless. Drilling dust is vacuumed at source with a HEPA filter rather than swept across rooms. Painter’s tape frames hole locations on delicate finishes to keep edges crisp. Drop cloths and corrugated mats isolate the path from mixing to work zone, and tools rest on trays that catch drips.

During capping, a soft brush and damp rag remove residue immediately. Final cleanup proceeds from the far corner toward the exit, lifting coverings and checking that thresholds and vents are clean. A short punch list confirms that baseboards are dust free, outlets are clear, and floors are dry. The goal is to leave the room ready for furniture as soon as curing allows.

Finishes flooring and post lift reassembly

Interior lifting often happens under finished spaces. Coordinating with flooring types and trim speeds the return to normal life.

Tile hardwood carpet and resilient floors

This overview explains how finish materials respond to subtle elevation changes. Tile tolerates uniform movement when grout lines are intact; crews lift in small increments and monitor lippage at transitions. Hardwood needs humidity aware timing so expansion gaps remain healthy. Carpets stretch back easily after work, while resilient floors appreciate gentle heat and weight distribution during the first day.

Thresholds between rooms get special attention. As Mudjacking returns plane, reducers or transitions may sit more cleanly, removing prior toe catches. Technicians verify door sweeps and weatherstripping so function improves along with structure. Owners appreciate that the space looks and works better than before.

Where finishes are especially delicate or historic, mock lifts in small zones confirm behavior before full production. That step calms nerves and protects value.

Cabinets baseboards doors and built ins

This overview covers details that set the tone in finished rooms. Crews check baseboard reveals and caulk lines, tightening any gaps that appear as the slab returns to level. Cabinet plinths and islands are monitored for racking; tiny shims may keep faces flush while the subbase regains contact.

Door swing and latch engagement are tested during the lift. A millimeter here matters, so adjustments are made in real time. With Mudjacking proceeding in controlled steps, finishes return to alignment and the room reads as intentional rather than disturbed.

If appliances were moved, sliders or temporary boards protect floors during re entry. Everything goes back to original locations once patches pass a simple hardness check.

Indoor safety air quality and comfort

People and pets are part of the job inside. Clear communication and small precautions create a calm, safe experience.

Ventilation PPE and noise planning

This overview describes a light touch approach to comfort. Fans and slightly open windows support fresh air flow away from living areas. Technicians wear hearing and respiratory protection during drilling and keep noise within predictable windows. A simple whiteboard at the door outlines the day’s steps and when each room reopens.

Homeowners know where to walk and what to avoid, and kids understand the boundaries. With expectations set, Mudjacking feels less like construction and more like a service call.

Material handling spills and household protection

This overview explains how to prevent and respond to the rare mishap. Buckets sit on trays, lids stay on when moving, and towels are staged at pinch points. If a drip reaches flooring, a damp wipe handles it before it cures. Tools are cleaned before they travel past finishes, and the path to the exit remains covered until the final inspection.

Simple discipline avoids the dramatic cleanup stories that give interior work a bad name. The routine is quiet and repeatable.

Scheduling curing and return to service indoors

Indoors, the path back to normal use is short when protection and patience align. The sequence is clear and the checklists are simple.

Realistic timelines and temperature awareness

This overview sets expectations. Most interior Mudjacking projects reach initial stability quickly, but full strength develops over time. Gentle traffic may resume soon after capping, while heavy items wait for the next check. Temperature and humidity affect both slurry and patches; maintaining room conditions within normal ranges helps hydration and keeps finishes comfortable.

Owners get a concise care guide—avoid dragging appliances, keep ventilation light for a day, and report any unusual sounds at joints. With these notes, the space moves from project to everyday life smoothly.

Verifications thresholds and final polish

This overview explains the last pass that makes the work feel complete. Levels confirm plane across doorways, thresholds meet cleanly, and drains still run true. Ports blend with surrounding textures and colors, and baseboards wipe free of dust. The team returns furniture carefully and confirms that doors latch and swing without rub.

A short photo set documents before and after elevations, serving as a reference for future maintenance or adjacent projects. The finished room feels stable, clean, and ready.

Coordinating with other scopes and long term planning

Interior lifts often sit within a broader plan—remodels, utility upgrades, or seasonal maintenance. Aligning schedules saves time and improves results.

Working alongside trades and small remodels

This overview shows how leveling integrates with other work. Electrical and plumbing tasks sometimes need a stable floor to set equipment or pedestals; performing Mudjacking first gives those trades a reliable base. Flooring contractors appreciate even plane and predictable transitions, and trim carpenters can fine tune reveals with confidence.

If an area is too compromised for lift, documentation supports future Replacement planning without guesswork. Clear notes and elevations make spring or summer projects faster.

Preventing recurrence moisture and load management

This overview ties structure to simple habits. Manage sources of moisture—sump discharge, downspouts, or appliance leaks—so the subbase stays dry. Distribute point loads with pads under heavy equipment and store dense items near supports. Where adjacent outdoor slabs influence interior movement, consider exterior Leveling or Lifting to keep transitions aligned.

Periodic checks after storms or seasonal changes catch small shifts early. With a stable base and thoughtful care, interior lifts last and the room stays quiet underfoot.

A quiet return to normal

A successful interior lift is measured by how ordinary the room feels the next day. With careful mapping, contained workflows, and patient, incremental lifts, Mudjacking restores confidence without sacrificing comfort or cleanliness. Plan the steps, protect the finishes, and let a disciplined process bring floors back into line. Contact us when you are ready to map your project, our team will help you choose the right sequence and make the experience simple from start to finish.