Mudjacking during a Minnesota winter demands timing, technique, and expectations that match the season. Cold air, frozen subgrades, and short daylight windows change how crews stage access, select mix temperatures, and manage post lift protection. When homeowners understand how heat, moisture, and traffic interact below freezing, projects move smoothly and the results last. With a smart plan that respects weather phases and site conditions, Mudjacking can restore safe access and clean lines even when frost lingers at the edges of slabs.

How temperature affects slurry behavior and lift stability

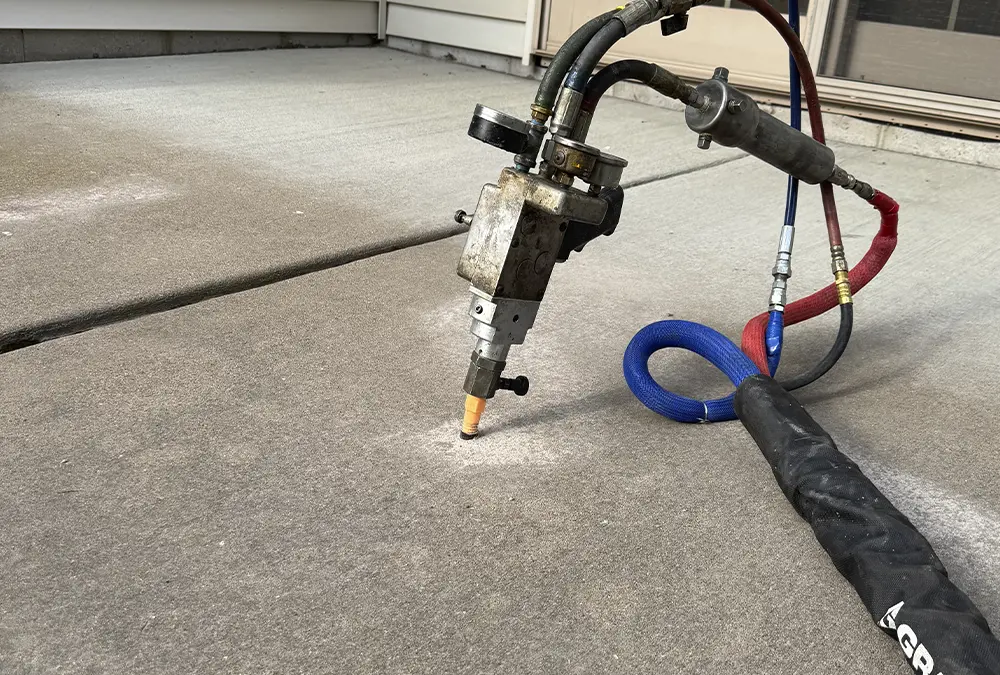

Cold weather changes the chemistry that governs set and strength gain. Mix water cools rapidly, cement hydration slows, and the surrounding soils may be partially frozen, which alters how material spreads and bonds. A disciplined approach to batching and temperature control helps crews deliver predictable lifts. With the right safeguards, Mudjacking achieves uniform support that holds through repeated thaw cycles.

Hydration rate heat loss and field batching in the cold

Cold conditions reduce early reactivity, so crews compensate with mix temperature and tight staging. Heated water, insulated hoses, and covered mixing stations keep temperatures in the effective zone from the first bag to the last. Measured batch sizes prevent long waits between holes, and a nearby tool mat limits exposure to wind.

Maintaining a steady rhythm prevents slurry from dropping below its target temperature mid injection. The goal is consistent viscosity so it flows to voids, seats evenly, and resists segregation. When the mix remains warm, Mudjacking fills pockets thoroughly instead of stacking near ports. That uniform base supports panels without cold joints that could settle under early loads.

Even with careful batching, crews watch ambient swings hour by hour. If a front moves in, they shorten the working radius so holes are injected and capped quickly. Keeping the operation compact preserves heat and keeps the material’s behavior predictable.

Subgrade condition frost lenses and void access

Soils do not freeze uniformly; south exposures may be open while shaded edges hold frost. Crews probe beneath panels to confirm where voids remain accessible and where lenses could redirect flow. The plan adjusts to inject from warmer edges first, using small lifts that confirm bearing without forcing material against ice.

When frost is shallow, Mudjacking can proceed with incremental staging that allows heat from the mix to soften a path. Where frost is deeper, teams may defer a panel until a warming window arrives. Working with subgrade reality protects the lift from being trapped by seasonal ice and ensures the base binds to soil rather than a temporary layer.

Access holes are positioned to chase known cavities rather than fight frozen pockets. That strategic placement minimizes pressure, reduces waste, and yields a cleaner, more reliable outcome.

Scheduling windows and weather breaks that work in Minneapolis Saint Paul

Winter is not a monolith; it moves through phases that open and close opportunities. Crews watch multi day forecasts for stable highs and manageable winds, choosing windows that allow setup, lift, and protection without rushing. With a flexible schedule and clear communication, Mudjacking fits safely between storms.

Picking the right 48 to 72 hour window

A good window offers daytime highs above the deep freeze and nights that avoid extreme wind chills. The first day sets ports and performs initial lifts; the second verifies elevations and finishes protection. If temperatures dip, insulated covers keep patches safe while hydration advances.

Planning around sun angles matters, too. South facing panels warm earlier and let Mudjacking begin while shaded segments wait an hour or two. That staggered sequence respects microclimates on site and keeps progress steady. By matching lift order to thermal reality, crews finish more panels in fewer trips.

Communication with owners locks in access and ensures vehicles are staged away from work zones. That coordination reduces delays and keeps protective measures undisturbed during the critical overnight period.

Reset plans after snow melt and refreeze

Snow events create meltwater that seeps into joints, then refreezes as temperatures fall. Teams schedule a short delay after plowing so standing water can drain or be removed before drilling. Dry surfaces accept patches better, and cleaner edges simplify final sealing.

Where melt tracks toward drive aprons, Mudjacking follows with small lifts to close gaps and restore slope. The aim is to move water away from entries before the next refreeze. Crews confirm that downspouts and sump outlets are not loading edges during overnight cycles.

If a sudden cold snap follows a warm day, work pauses and insulated covers protect recent patches. Flexibility preserves quality when weather swings.

Mix design protection and curing tactics that pay off in winter

Cold changes details that crews can control, from water temperature to surface protection. Getting those details right keeps timelines realistic and outcomes strong. Each tactic supports the next, forming a simple system that delivers dependable results.

Warm water insulated logistics and admixture strategy

Heated mixing water raises initial slurry temperature, buying working time in the air and under the slab. Insulated hoses and covered mixing stations limit heat loss between batches. Where appropriate, non chloride accelerators help early set without risking rebar corrosion in nearby structures.

Batch size matches the pace of the crew so material is placed while warm. Consistency prevents variability in lift response. With predictable flow, Mudjacking reaches remote pockets and forms a continuous base that resists early traffic and freeze thaw cycles.

Documentation matters—crews note water temperatures, batch intervals, and ambient conditions. That record informs adjustments and gives owners confidence in the process.

Surface protection blankets cones and quiet curing

After ports are patched, insulated curing blankets shield the area from wind and radiative loss. Cones keep pedestrians and pets off curing spots, and light signage reminds everyone to wait until the morning sun softens surfaces. Protection stays in place through the coldest part of the night.

Gentle warmth under blankets boosts early strength gain so patches hold shape when covers come off. The goal is to emerge with clean, flush caps that blend with the surrounding surface. When Mudjacking includes minor alignment at thresholds, blankets also help maintain uniform temperature so joints cure evenly without hairline opening.

A brief morning check verifies hardness and appearance before normal use resumes. Small, consistent habits add up to durable outcomes.

Traffic management safety and liability in winter conditions

Cold weather narrows margins for pedestrians and vehicles. Good signage, routing, and temporary traction keep everyone safe while the work cures. Smart traffic plans protect the repair and the people using the space.

Routing detours and temporary traction

Cones and A frames define work zones and guide walkers around wet patches. Where detours cross snow, a light pass with sand provides traction without burying edges. For driveways, owners stage vehicles on the street until the morning check confirms readiness.

Clear communication sets expectations. Notes at entries indicate when sections will reopen and remind visitors to avoid dragging wheels across new patches. Because Mudjacking in winter often finishes near dusk, reflective tape and small lights improve visibility overnight.

On HOA and campus routes, teams coordinate with facilities for plow timing so blades do not clip raised edges accidentally. A quick map shows which joints are fresh and marked for caution.

Liability reduction through quick hazard removal

The fastest way to reduce winter liability is to eliminate trip points that catch toes beneath slush. Targeted lifts remove abrupt lips and restore ADA friendly transitions. That immediate improvement matters near mailboxes, school paths, and storefronts.

Because Mudjacking returns areas to service quickly, closures are shorter and signage simpler. Documenting before and after elevations, plus photos, demonstrates risk management to boards and insurers. The smoother the routes, the lower the chance of incident during freeze thaw swings.

Integrating winter work with broader maintenance plans

A cold season lift works best when it feeds into spring checkups and summer sealing. Thinking in seasons creates a loop that keeps slabs stable and attractive. The right sequence spreads investment sensibly and prevents repeat issues.

Winter triage spring follow up and summer sealing

Use winter to address the worst hazards and stabilize panels that move under traffic. As temperatures moderate, crews return for fine tuning and joint sealing that last longer in mild weather. Summer adds surface sealing where appropriate to reduce absorption and keep edges tight.

That seasonal cadence respects budgets and weather realities. It ensures Mudjacking support is in place when freeze thaw cycles resume next year. Homeowners enjoy safer access now and fewer surprises later.

For properties with repeating settlement patterns, simple drainage tweaks and regular cleaning compound the effect. Little habits make structural improvements go farther.

Coordinating with adjacent scopes and trades

Cold months are a great time to align schedules with other work. Electricians, landscapers, and carpenters often have winter tasks that touch slabs. A level surface helps Installation crews set steps and handrails correctly, while plumbers appreciate stable equipment pads near entries.

When connected panels belong to different owners—city walks, HOA paths, or shared drive aprons—coordination keeps grades consistent across boundaries. A unified plan prioritizes Leveling where transitions meet and sets the stage for spring finishing.

If a panel is too compromised for lift, clear documentation supports Replacement planning. Winter notes lead to efficient warm weather work without re diagnosing the site.

Case patterns and microclimates across the Twin Cities

Not all cold is equal. Open prairie winds, shaded tree lines, and urban heat islands create microclimates that influence scheduling. Recognizing those patterns focuses effort where it counts.

South edges aprons and wind channels

South facing edges warm quickly and are ideal early targets. Driveway aprons that collect plow piles may stay colder and need later attention. Narrow corridors between houses funnel wind that strips heat; crews limit open time for holes in those spots.

Mapping these zones allows Mudjacking to proceed in a logical order that uses daylight efficiently. The result is steady progress and consistently neat patches no matter the block.

Shade lines under evergreens and along fences remain cooler. A small shift in timing there prevents slow set and preserves crisp finishes.

Urban cores river valleys and open lots

Downtown surfaces benefit from ambient warmth off buildings, opening small windows even on cold days. River valleys trap cold air and hold frost, so panels near banks may need a slightly warmer forecast. Open lots catch wind; screens and covers become more important to protect curing patches.

These local nuances drive daily decisions. With observations logged, teams refine playbooks for each neighborhood and deliver repeatable quality.

Tools materials and crew readiness for winter efficiency

Winter work rewards preparation. Kits that emphasize warmth, visibility, and tidy logistics cut setup time and preserve quality in the cold. A few focused upgrades make long days feel manageable and professional.

Warmth visibility and staging kits

Insulated water containers, hose wraps, and portable heaters keep materials in range. Reflective vests, cone lights, and headlamps extend safe working hours. Compact mats, trays, and covers keep sites neat and prevent paste from touching decorative surfaces.

Spare brushes, rags, and painter’s tape prevent small issues from becoming stains. Crews that carry these basics resolve surprises in minutes. The visible care builds homeowner confidence while the technical work proceeds calmly.

A simple checklist at the truck door confirms water temperature, blanket count, and signage before departure. That routine keeps quality high even when conditions are challenging.

Documentation communication and homeowner confidence

Short forms capture ambient temperature, wind, water temperature, batch times, and reopen times. A photo set before and after each panel shows alignment and clean finishes. Owners receive a brief summary of what to avoid overnight and what to expect in the morning.

Because Mudjacking in winter is as much about planning as lift, clear notes become part of the service. They help everyone remember what worked and where to focus next time. Confidence grows with each well executed cold weather project.

Gentle close for the season

Cold weather does not have to pause every improvement. With careful scheduling, warm mixes, and thoughtful protection, Mudjacking corrects hazards and restores smooth movement even when frost lingers. Align winter work with spring follow ups, keep notes, and let small routines carry the results forward. Contact us when you are ready to plan the next step, our team is happy to map the right window and make the process uncomplicated from start to finish.