Mudjacking remains a familiar method for lifting settled concrete, and a spotless finish depends on thoughtful planning from start to finish. Around Minneapolis Saint Paul, homeowners want sturdy slabs and a backyard that still looks manicured when the work wraps. With clear access routes, careful slurry control, and gentle aftercare, you can protect plantings, edging, and hardscape while delivering a result that reads as improvement rather than disruption. This guide focuses on practical, field tested cleanup habits that make Mudjacking look as good as it performs through every season. It also coordinates well with adjacent Leveling and Lifting tasks around connected slabs.

Why cleanup planning matters for lasting results

A precise lift can fall short if residue distracts from the restored surface. Cement fines set quickly on pavers and border stones, and poorly managed rinse water can carry paste into mulch where it hardens. By setting access paths, staging tools, and defining rinse zones before drilling, crews keep the site orderly and protect the landscape’s health. These simple steps elevate the outcome and reduce callbacks, turning Mudjacking day into routine care instead of a messy project. The same preparation pairs smoothly with future Polyjacking touch ups when sites warrant that approach.

Access routes staging and surface protection

This overview introduces how small preparations prevent big messes during Mudjacking. Define a hardscape path for equipment to avoid ruts in turf and protect irrigation heads. Stage plywood runners where carts will roll and use breathable fabric to shield adjacent beds so foliage does not overheat. Place a compact tool mat near the work zone to catch drips and keep port patches neat while they cure.

Lay out a hose and clean water source before drilling begins. A quick rinse of dust around holes prevents fines from spreading into grass where they can harden. Set shallow trays under mixing spots so splatter does not mark decorative concrete. A handheld vacuum ready at the drill reduces airborne dust and shortens end of day cleanup.

Keep a soft brush and a bucket within reach at the slab edge. Wiping ports immediately after injection prevents raised rims from setting. If a streak appears, brushing while damp removes it without scrubbing. Waiting until the end gives residue time to bond with porous surfaces, turning a ten second wipe into a tough spot.

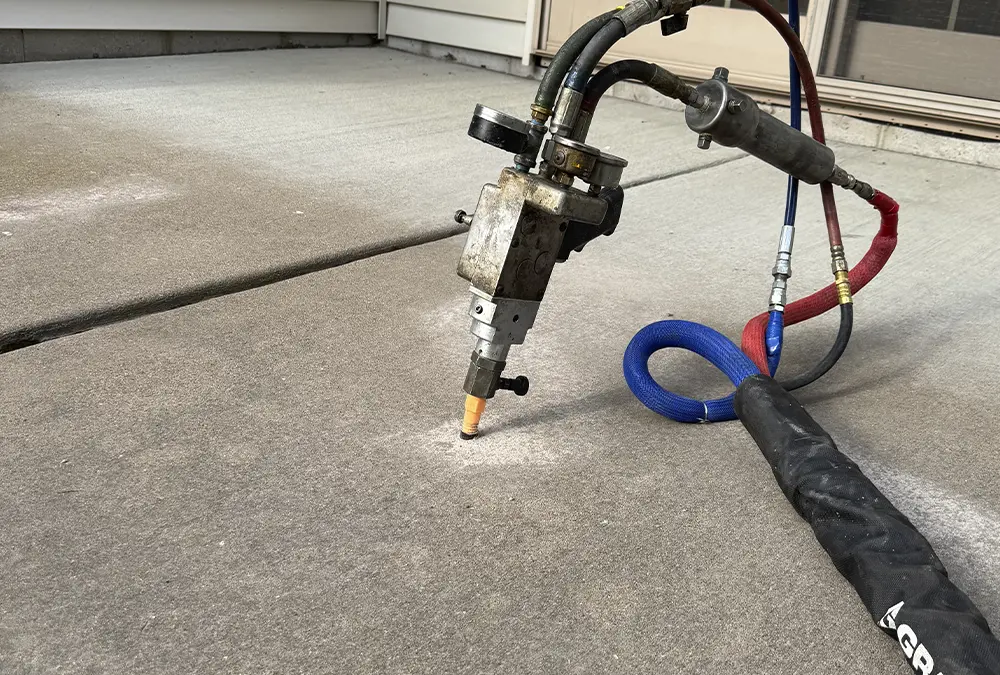

Controlling slurry splatter dust and runoff

This overview addresses the material characteristics unique to Mudjacking and how to keep them in check. Cement fines travel on wind while heavier splatter drops near ports. Use a low spray hose pattern to pin dust close to the ground without forcing water into joints. Vacuum dust as it forms instead of sweeping it into beds. Where gardens border the slab, set light shields that redirect splatter back toward the work area.

Runoff management matters once rinsing begins. Direct water away from freshly patched ports and onto turf where absorption is high. Avoid washing across mulch because paste can bind fibers and harden into crusts. Rinse tools into a settling bucket so fines drop out rather than flowing into drains. These habits keep cleanup contained and protect soil structure around roots.

At driveway crossings and stamped surfaces, protect joints with a quick pass of painter’s tape to keep paste lines straight. Test any cleaner stronger than water on a hidden spot to avoid hazing sealers. Gentle methods first protect color and surface sheen while still lifting fresh residue.

Protecting lawns gardens and hardscape during Mudjacking

Landscapes are living systems, and small decisions during the job make big differences days later. Roots need air, turf needs even grade, and pavers need clean edges. Mudjacking respects all three by isolating messy tasks and sequencing lifts to minimize tracking. When the concrete rises smoothly and the site stays tidy, the finished look reads as intentional and well cared for. Thoughtful staging also prepares the area for follow up Installation needs such as edge restraints or new panels.

Turf health edging integrity and irrigation safety

This overview explains how to preserve softscape while equipment moves in and out. Lay temporary paths with plywood or composite mats to spread load and prevent tire depressions on moist soil. Keep heavy buckets off turf to avoid suffocating grass. Mark irrigation heads and valve boxes so carts do not nick risers during turns. After work, a light roll or topdressing evens minor impressions before they become ruts.

Edging along beds deserves special care. Vibrations during Mudjacking can shift bricks or aluminum strips that define borders. Check alignment after each lift and tamp gently to maintain crisp lines. Where mulch abuts the slab, pull it back a few inches before rinsing so paste does not bind fibers to concrete. Return the edge after cleanup to frame the repair with a clean, intentional look.

Water and cement are rough on shallow roots. Use low shields and position buckets on mats so splash from mixing areas stays off shrubs and perennials. If foliage catches a small amount of slurry, rinse immediately with gentle water to prevent spotting. These quick reactions preserve plant health and keep beds looking fresh.

Pavers stone accents and decorative concrete

This overview covers how to treat hardscape elements that complete outdoor spaces. Pavers can wick fines into joints if rinse water crosses repeatedly. Lift dry dust with a shop vacuum first, then rinse lightly from the high corner so water exits the field rather than pooling. Stone caps and seat walls respond best to cotton rags, not abrasive pads that can alter sheen.

On stamped or stained concrete, avoid strong alkaline cleaners that can haze sealers. If a section is too distressed to save, a clean site simplifies later Replacement decisions. Start with water and a soft brush; escalate only if needed and confirm with the sealer data. Protect the topcoat to maintain color depth and keep the repaired area visually consistent with adjacent sections.

Small chips at slab edges may appear after a lift when weak corners meet new alignment. Smooth any sharp nibs with a rubbing stone and blow away dust before a final rinse. The aim is a smooth, toe friendly edge that matches existing textures.

Setting expectations for neighbors and shared spaces

Communication makes cleanup smoother in neighborhoods HOAs and campuses. Clear timing and simple routing cues keep foot traffic out of wet areas and reduce interruptions. When everyone understands the sequence, Mudjacking days feel like routine maintenance instead of disruption.

Notices routing and temporary closures

This overview introduces small cues that help people move safely around the site. Post a concise note the day before work with a time window. Use cones and a friendly printed sign to guide walkers around the section being lifted. Route strollers and carts along an alternate path and keep gates propped for easy detours. Neighbors appreciate knowing where to go and when surfaces will be ready again.

If the job crosses driveways, coordinate start times with residents. Lifting earlier in the day leaves time for patch curing and light rinsing before evening traffic. Where pets are common, remind owners to keep leashes short near work zones to avoid wet patches and tools. A little choreography turns complexity into calm.

On school and campus routes, coordinate with facilities teams so bell schedules align with brief closures. Prioritize heaviest footpaths first, reopen them quickly, and move cones as each panel returns to use. That rhythm keeps the community moving while work progresses.

Visual standards and final walkthrough

This overview explains how to document results and agree on what clean means before packing up. Take quick before photos of edges beds and decorative surfaces near the zone. After rinsing, repeat shots to confirm borders are straight joints are free of paste and foliage is unspotted. A shared checklist keeps teams consistent across properties and seasons.

Invite the owner or manager for a brief walkthrough. Point out patched ports, confirm slopes toward drainage, and share recommendations for joint sealing or grading adjustments. Set a simple plan for watering turf repairs and for waiting periods before heavy traffic. Ending with clear expectations turns cleanup into part of the service.

Rinse water tools and eco smart disposal

Cleanup is also about what you do with what you collect. Slurry and rinse water contain cement fines that can cloud ponds and bind soil if dumped carelessly. A few easy habits during Mudjacking cleanup keep gardens drains and waterways safe while maintaining a tidy look.

Capturing fines settling and safe disposal

This overview introduces capture methods that work on residential sites. Rinse tools into a settling bucket so solids drop out before water is poured onto gravel or turf. Do not send slurry into storm drains, and avoid washing into mulch where paste can cement fibers. For larger jobs, set shallow trays lined with filter fabric to catch fines before they spread.

Once solids settle, the remaining water can be dispersed across lawn where dilution is high. The collected fines can be scraped into a waste bag after they harden. Keeping cement paste out of beds preserves soil structure and prevents a crust that sheds water from root zones. These steps are quick inexpensive and make a visible difference in how clean a site reads.

Where regulations or HOA rules apply, post the method you are using so neighbors see the care taken. A small sign by the settling bucket turns a behind the scenes practice into a trust builder.

Tool care staging and site restoration

This overview explains how tool hygiene supports a neat finish and future efficiency. Clean hoses and mixers before paste sets so next day starts are smooth. Coil cords and stack mats away from plantings to avoid broken stems. Remove all shields, then sweep or blow remaining dust from edges so borders look crisp. A final light rinse unifies surfaces and makes the lift look like it has always been there.

Return furniture and planters only after confirming slopes and dry patches. If soil was disturbed, lightly rake and water to settle it. The last look should feel intentional and complete.

Post lift care that protects landscaping and structure

Cleanup is the bridge to long term performance. A deck or walk lifted by Mudjacking will stay attractive when moisture is managed and surfaces are protected. Simple routines and timely sealant work keep the site stable and your landscape thriving.

Joint sealing drainage checks and seasonal routines

This overview ties structural protection to everyday tasks. Seal joints once patches cure so water cannot re enter at vulnerable lines. Confirm that downspouts sump outlets and sprinklers do not load slab edges. Watch the first rain after the job and nudge gravel or soil to guide flow away from borders. These small actions reinforce the repair without heavy effort.

Seasonal routines keep appearances high. Sweep grit that can scratch surfaces and remove leaves before they stain. Where snow removal occurs, set markers to prevent blade strikes at lifted edges. In spring, inspect for any minor settlement and address early so cleanup remains simple year after year.

Plant health is part of the picture. Water turf lightly where mats sat, trim any bruised foliage, and top up mulch that was pulled back. A little attention restores a manicured look and helps the yard bounce back quickly.

Gentle cleaning methods that respect finishes

This overview recommends techniques that balance effectiveness and safety. Start with water and soft brushes, escalating only when needed to protect sealers and color. Avoid strong acids or alkaline cleaners that can haze decorative surfaces. On pavers, use low pressure and fan tips; on stamped concrete, follow the sealer manufacturer’s guidance. The goal is a fresh natural appearance without altering sheen.

If tire marks appear during staging, catch them early with mild detergent and a soft pad. Dry sweeping first lifts abrasive grit so cleaning works better. Document any stubborn spots and plan a gentle second pass rather than scrubbing once everything is dry.

These measured approaches keep hardscape looking unified and help your Mudjacking lift blend seamlessly into the overall design.

A cleaner finish for every season

When lifting is done, how the site looks and functions is what everyone remembers. Thoughtful cleanup turns Mudjacking into a complete improvement that honors your landscape and protects its health. With smart staging tidy rinsing and simple aftercare your walkways and beds look refreshed for guests in every season. Contact us if you are mapping next steps and want help planning details, our team expert in Mudjacking is ready to make the process smooth from start to finish.