If you’ve heard conflicting advice about Polyjacking Concrete, you’re not alone. As this modern lifting method replaces messy, heavy slurry techniques, myths tend to spread, especially online. Below, we break down the most common misconceptions and match them with field-tested realities, so you can make an informed decision for your driveway, garage, sidewalk, or patio.

Myth #1: “Polyjacking Concrete is Just Expensive Marketing”

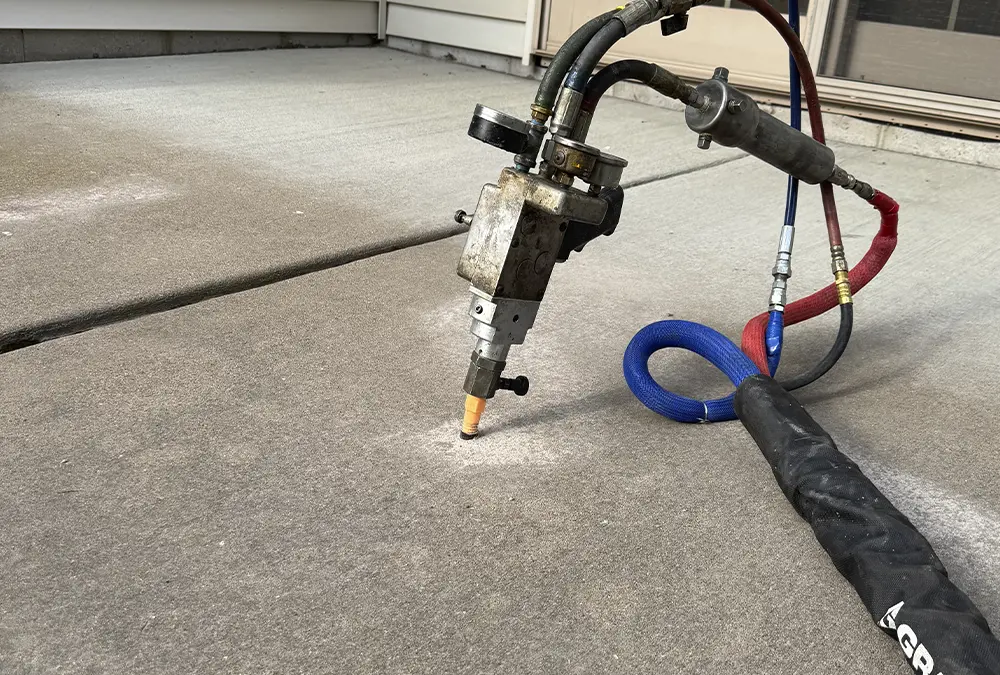

Reality: The performance difference is measurable. Polyjacking Concrete uses a high‑density, closed‑cell polyurethane that expands to fill voids and re‑establish bearing with minimal added weight. Because it cures fast and requires smaller ports, your surface returns to service quickly and cleanly. Over the life of the repair, fewer callbacks and minimal landscape disturbance often make it more cost‑effective than demolition or slurry-based lifts.

Why It Matters

- Lightweight foam reduces the chance of re‑settlement in weak soils.

- Small injection ports patch nearly flush—no large, visible plugs.

- Same‑day usability keeps homes and businesses moving.

For projects where budget, downtime, and appearance all matter, Polyjacking Concrete is a data‑driven upgrade, not hype.

Myth #2: “It Won’t Hold Heavy Loads”

Reality: Properly specified foams deliver impressive compressive strength while adding negligible mass to fragile subgrade. When installed by trained crews, Polyjacking Concrete supports garage aprons, RV pads, and commercial entries without transferring excessive weight to failure planes.

Field Takeaways

- Match foam density to the expected load and slab thickness.

- Use a mapped injection grid to achieve uniform lift and bearing.

- Verify elevations with laser monitoring during the lift.

Myth #3: “It Can’t Handle Moisture or Winter Freeze Thaw”

Reality: Closed‑cell polyurethane resists water intrusion and washout. In climates like Minnesota, Polyjacking Concrete paired with joint sealing and sensible drainage stands up to seasonal expansion and contraction far better than water‑absorbing materials.

Practical Steps

- Seal joints the same day as the lift to block surface water.

- Extend downspouts and fix negative grading around slabs.

- Schedule a spring/fall check to confirm elevations and sealant health.

Myth #4: “The Holes Are Big and Obvious”

Reality: Typical ports for Polyjacking Concrete are about ⅝″, far smaller than the 1½″–2″ holes common with slurry methods. With proper patching and color‑matching, repaired ports blend in with the surrounding slab.

Finish Details That Matter

- Clean edges before patching for a tight bond.

- Use a compatible patch material and tool it to match texture.

- Keep photos for your records to show future buyers the work was done properly.

Myth #5: “Results Don’t Last”

Reality: Performance depends on diagnosis and execution—not luck. When crews address drainage, map injections, and seal joints, Polyjacking Concrete maintains elevation year after year. The foam itself is chemically stable once cured.

Long‑Term Stability Checklist

- Root‑cause fix (water, roots, irrigation leaks).

- Strategic grid and incremental injections.

- Post‑lift sealing and a simple maintenance plan.

Myth #6: “It’s Only for Minor Settling”

Reality: From sidewalk lips to sloped garage floors and pool decks, Polyjacking Concrete handles a wide range of offsets. Limitations exist, full‑depth fractured slabs or active washouts may require selective replacement, but most residential sinking is a great fit.

When It’s Not Right

- Heaving clays that push slabs upward.

- Ongoing utility leaks or active soil washouts.

- Structural fractures through full slab thickness with differential movement.

Myth #7: “Any Contractor Can Do It the Same Way”

Reality: Results vary with training, equipment, and process control. Look for teams that discuss port layout, foam specs, cure times, and sealing in writing. A disciplined plan is your best predictor of success with Polyjacking Concrete.

What to Ask Before You Hire

- Do you provide a mapped injection plan and elevations before/after?

- Which foam densities do you use for different loads?

- What’s included in your sealing and aftercare?

Myth #8: “It’s Messy Like Mudjacking”

Reality: One of the key advantages of Polyjacking Concrete is cleanliness. Smaller ports, no slurry splatter, and minimal wash‑down mean a tidy jobsite and no ruts in the yard.

Tidy Jobsite Practices

- Stage tarps and vacuum ports during drilling.

- Keep hoses organized and protect adjacent finishes.

- Patch, seal, and power‑clean edges before hand‑off.

The Process, Step by Step (What Good Looks Like)

- Assessment & Diagnosis — Identify water sources, voids, and offsets.

- Grid & Port Layout — Design a lift plan that respects load paths and joints.

- Controlled Injection — Small pulses, constant monitoring, zero overshoot.

- Finish & Seal — Patch flush, seal joints, document elevations.

- Care Plan — Drainage tune‑ups and periodic sealant renewal.

When executed with care, Polyjacking Concrete outperforms heavy slurry lifts on speed, appearance, and long‑term stability.

Minnesota Climate: Why This Method Shines Here

Freeze, thaw cycles, spring saturation, and wind‑driven evaporation challenge slabs across the Twin Cities. Closed‑cell foam resists water uptake, and the light weight avoids compounding weak soils. For homeowners who value clean work and same‑day use, Polyjacking Concrete is the climate‑smart choice.

Ready to Separate Myth from Reality?

If you want a clean, durable solution supported by process, not rumor, learn more about Polyjacking Concrete and see how a mapped lift can restore safety and curb appeal fast. We’ll walk you through the plan, the ports, and the patching so there are no surprises.

Prefer a side‑by‑side comparison with costs, timelines, and maintenance? Contact us to start with Polyjacking Concrete for a transparent scope and a clear outcome.

For engineering context on modern concrete maintenance, see the Federal Highway Administration resources.